Why Centrifugal Fans Are Vital for HVAC and Industrial Systems

You count on a centrifugal fan to help your hvac systems work well. This system pushes air in a good way, so your indoor space stays nice and safe. When you pick a good centrifugal fan, you can control the temperature and get rid of bad particles inside. LONGWELL is a brand people trust, and it gives you strong and energy-saving choices for any system. You see real changes that make your air better and help every system work better.

Key Takeaways

Centrifugal fans push air well by spinning curved blades. This makes strong airflow and pressure for HVAC and industrial systems.

These fans help clean indoor air by taking out dust and pollutants. They also help control temperature and humidity for comfort and safety.

Using energy-saving centrifugal fans can lower energy bills by up to 50%. This is because of smart designs and advanced motor controls.

Industrial centrifugal fans are made strong to handle heat, dust, and chemicals. This makes sure they work well in tough factory places.

LONGWELL has many types of high-quality centrifugal fans you can customize. They deliver fast and give expert help for any system need.

Centrifugal Fan Basics

How Centrifugal Fans Work

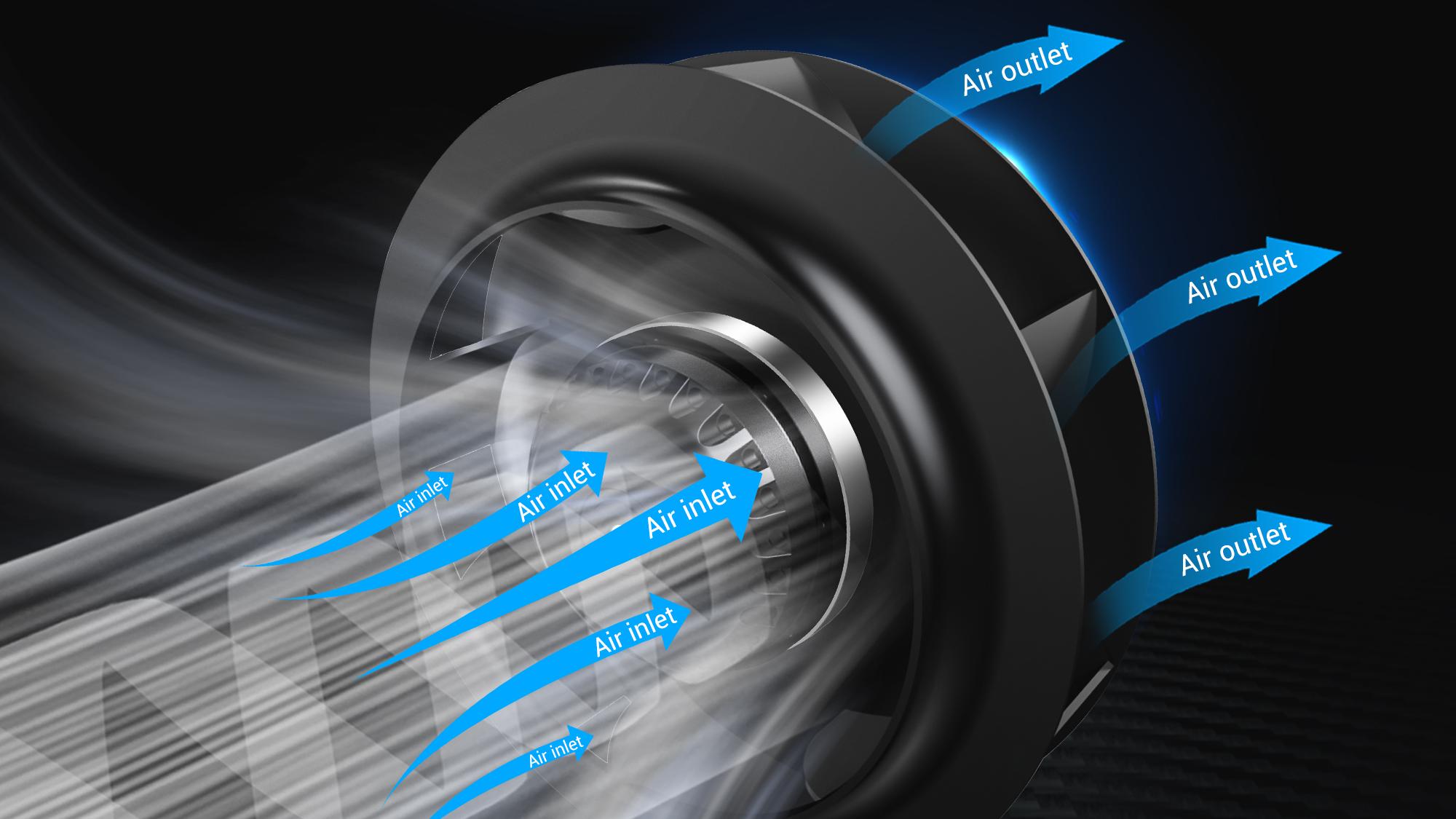

A centrifugal fan is a machine that moves air. It does this by spinning blades inside a round case. When you turn on the fan, the motor starts the impeller. The impeller has curved blades. These blades pull air into the middle. Then, they push the air out to the sides. This makes a pressure change. Air moves from the inlet to the outlet. The spiral-shaped case helps guide the air. It also makes the air pressure higher before it leaves.

Here is a table that lists the main parts of a centrifugal fan and what each part does:

Component | Description |

|---|---|

Fan Housing | Holds the impeller and directs the airflow |

Impeller | Spins to move air outward |

Inlet and Outlet | Openings for air to enter and exit |

Drive Shaft | Connects the impeller to the motor |

Motor | Powers the impeller |

Fan Blades | Curved to help move air efficiently |

Bearings | Support the spinning shaft |

Centrifugal fans work well in HVAC systems. They can handle high pressure. They also move air through long ducts or filters. You get steady airflow even if there are bends or blocks in the system.

Key Features and Advantages

Centrifugal fans have many good features. The design lets the fan make strong airflow and high pressure. This is great for moving air in tricky systems. The impeller shape and the case help lower noise and save energy. Some fans have backward-inclined blades. These blades help the fan use less power and work better.

Tests show that adding guiding vanes and special blade shapes can make the fan up to 5% more efficient. In HVAC systems, centrifugal fans often reach 60-80% efficiency. This is better than many other fans. You can see how the fan’s efficiency is found with this formula:

η_fan = (ΔP_fan × Q_fan) / H_fan

This formula shows how the fan uses its power to beat pressure drops and keep air moving. Using centrifugal fans saves energy and helps control temperature. You also get less noise and longer-lasting equipment because of smart design.

Centrifugal Fans in HVAC Systems

Air Circulation and Ventilation

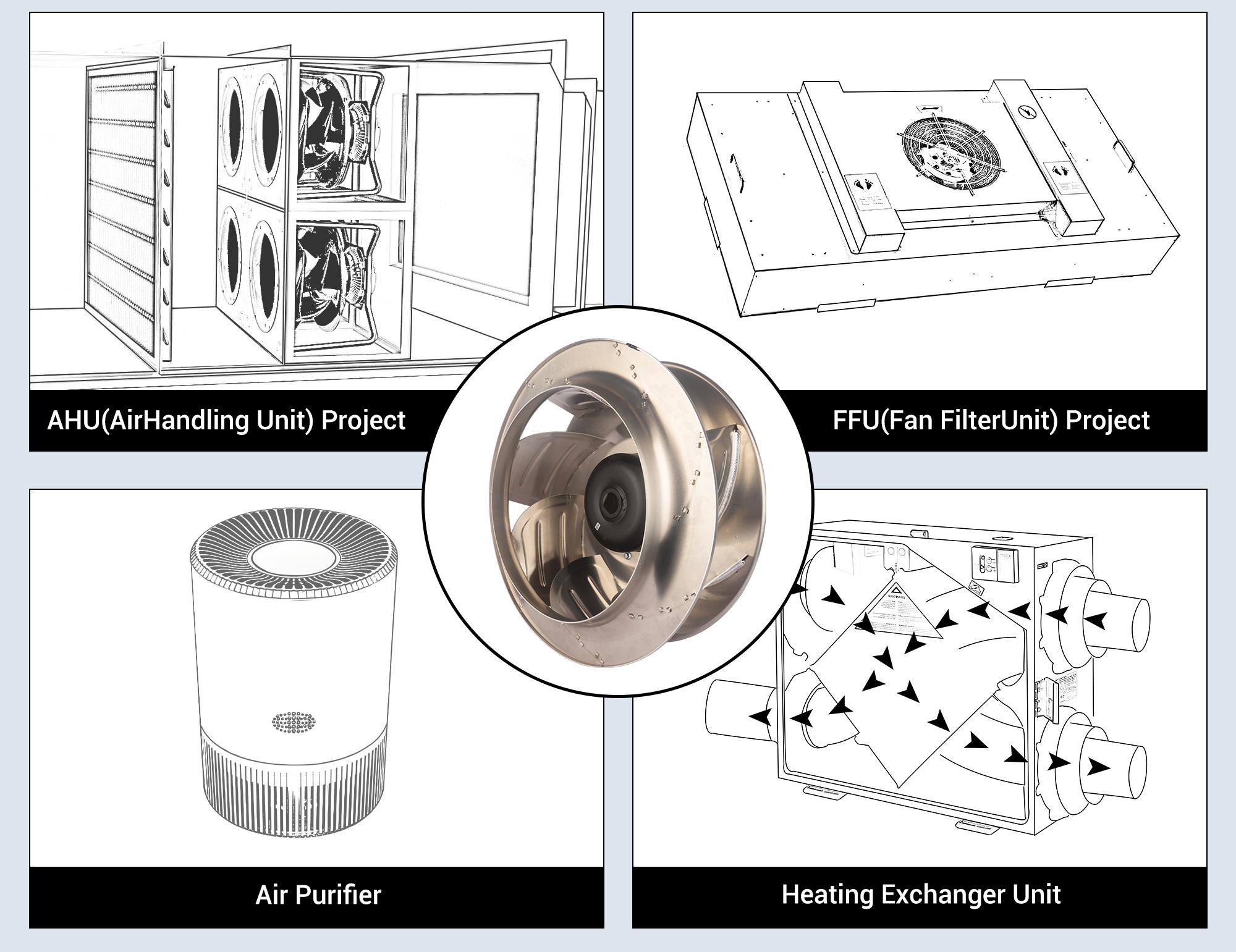

Good air movement keeps your indoor spaces safe and comfy. Centrifugal fans in hvac systems can handle different air amounts and pressures easily. These fans push air through long ducts, filters, and vents. This helps every part of your building get fresh air. You get steady airflow even if there are bends or blocks. This means you always have good air movement, which is important for ventilation.

When you use centrifugal fans in hvac systems, the air inside gets much better. These fans take out dust, allergens, and other tiny things from the air. You get cleaner air and a healthier place to be. Studies show that new designs, like adding a pressure regain unit, can make fans work up to 10% better. This happens because the air moves smoother and with less trouble. The table below shows how different tests prove centrifugal fans work well in hvac systems:

Measurement Type | Result / Description |

|---|---|

Ventilation Rate | 24.1%–26.6% lower than expected (CFD simulation and on-site testing) |

Pressure Difference | 33.7 Pa lower than manufacturer specifications (on-site fan performance curve) |

Volume Flow Rate Increase | 10% to 50% increase in different ventilation systems (CFD simulations under 3–5 m/s airflow) |

Efficiency Increase | Up to 10% increase through design optimizations (pressure regain unit in air handling unit) |

You can count on centrifugal fans in hvac systems to give steady air movement, even in big or tricky buildings. LONGWELL fans use smart technology to keep your system working well.

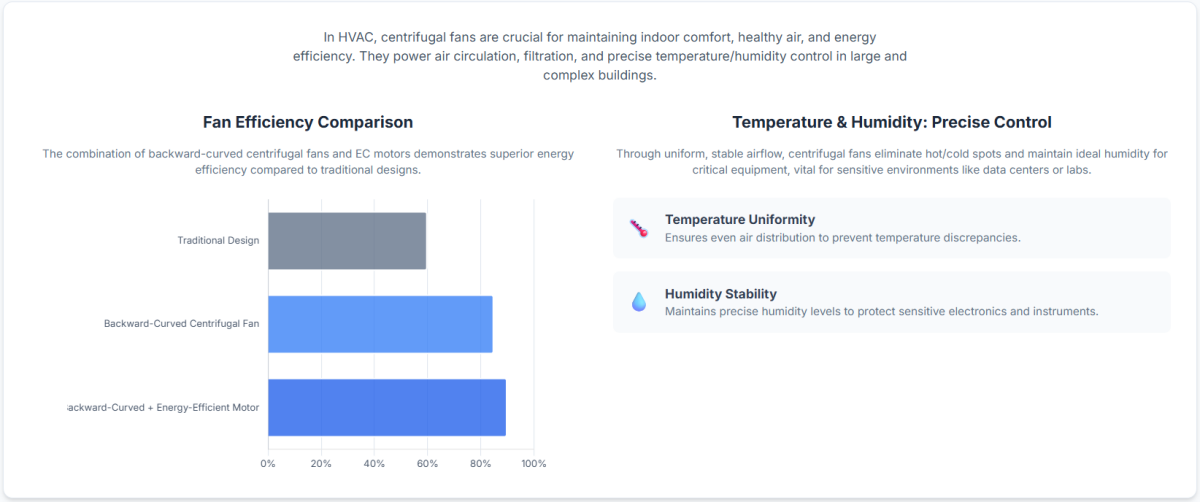

Temperature and Humidity Control

You want your indoor spaces to feel comfortable. Centrifugal fans in hvac systems help you control temperature and humidity well. These fans move air evenly, so you do not get hot or cold spots. They also help keep humidity just right. This protects your equipment and makes your space nicer.

With good air movement, you can keep temperature and humidity steady. This matters for offices, schools, hospitals, and homes. Your system can react fast to changes in weather or people. LONGWELL fans use smart sensors and controls. These features help you change airflow and keep the best indoor conditions all the time.

Energy Efficiency

You care about saving energy in your hvac systems. Centrifugal fans in hvac systems work well and use less energy. If you use fans with variable speed drives and energy-saving motors, you can cut energy use by 20% to 50%. Some factories have seen a 30% drop in energy costs after switching to backward curved centrifugal fans.

Data shows that smart controls, like PID controllers and sensors, help you save even more. You can lower costs by 6% to 73%, depending on the season and system use. These savings come from better airflow control and better motors. The table below compares different fan types and how much energy they save:

Fan Type | Efficiency Level | Energy Savings / Cost Reduction |

|---|---|---|

Traditional Fan Designs | 60% | N/A |

Backward Curved Centrifugal Fans | Up to 85% | N/A |

Backward Curved Fans + VFDs & Energy-efficient Motors | N/A | 20% to 50% energy savings |

Manufacturing Facility Upgrade to Backward Curved Fans | N/A | 30% reduction in operational energy costs |

You get the best from your hvac systems when you pick centrifugal fans that save energy. LONGWELL fans have certifications like ISO9001, CE, and UL/ETL. These show their quality and how well they work. You also get fast delivery and good customer support, so your system keeps running well.

Tip: Using centrifugal fans in hvac systems helps you get good ventilation, steady air movement, and a clean and healthy indoor space for everyone.

Industrial Ventilation Fan Applications

Airflow in Industrial Settings

Factories and plants need strong airflow to work well. An industrial ventilation fan moves a lot of air or gases. It works even if the air is dirty or very hot. You see these fans in cement plants, steel mills, and chemical factories. They help move air through long ducts and around corners. They also push air into hard-to-reach places.

Many factories use these fans for dust collection and drying. They also use them for moving things with air. In a cement plant, a strong fan can move dusty air without losing power. Fans for factories use special materials that do not break from heat or chemicals. This means they work well in tough places with high heat or chemicals.

Researchers use computer models and real tests to check these fans. In one study, a fan for cement plants worked just like the computer said it would. This shows these fans give the airflow you need in factories.

You find industrial exhaust fans in:

Material handling systems that move dust and powders

Industrial ovens and dryers for even heating

Chemical plants to remove fumes and gases

These uses show airflow is important for safe and good work.

Safety and Pollutant Removal

You want your workplace to be safe and clean. Factories often make dust, fumes, and bad gases. Industrial exhaust fans help remove dirty air and waste gases. They pull out bad air and send it through filters or scrubbers. This keeps the air inside safe to breathe.

Reports from steel plants show these fans catch over 98% of dust. The system uses hoods, ducts, filters, and a strong fan to pull air through. Tests before and after show dust drops below legal limits. Some filters, like pulse jet bag filters, can catch up to 99% of tiny dust. The fan keeps air moving so filters work well.

Researchers also check that the fan does not add more pollution. They test the air before and after it goes through the fan. This makes sure the fan helps clean the air, not just move it.

Note: Using the right industrial exhaust fans helps you follow safety rules and keep workers safe from bad air.

Reliability in Harsh Environments

You need equipment that works every day, even in rough places. Many factories have dust, heat, chemicals, or water. A heavy duty industrial fan must keep running in these tough spots. Fans with backward-curved blades work well in high-pressure systems. They keep airflow steady and make less noise. This is important in labs or data centers.

Long-lasting fans use special materials and smart designs. For example:

Corrosion-resistant metals and coatings stop damage from chemicals.

Aluminum frames help cool the motor and bearings.

Special bearings and strong shafts handle shock and shaking.

Some fans have IP68 ratings, so dust and water cannot get inside.

Long-life fans can run for 100,000 hours or more, even when hot.

You can make your fan last longer by cleaning it and checking for problems early. LONGWELL has fans made for tough places. You can pick special coatings or extra-strong parts for your needs. LONGWELL gives fast delivery, technical help, and many choices for all your factory needs.

Tip: Pick fans with the right materials and features for your place. This helps you stop breakdowns and keeps your system working well.

Industrial Applications and Custom Solutions

Customization and OEM/ODM Options

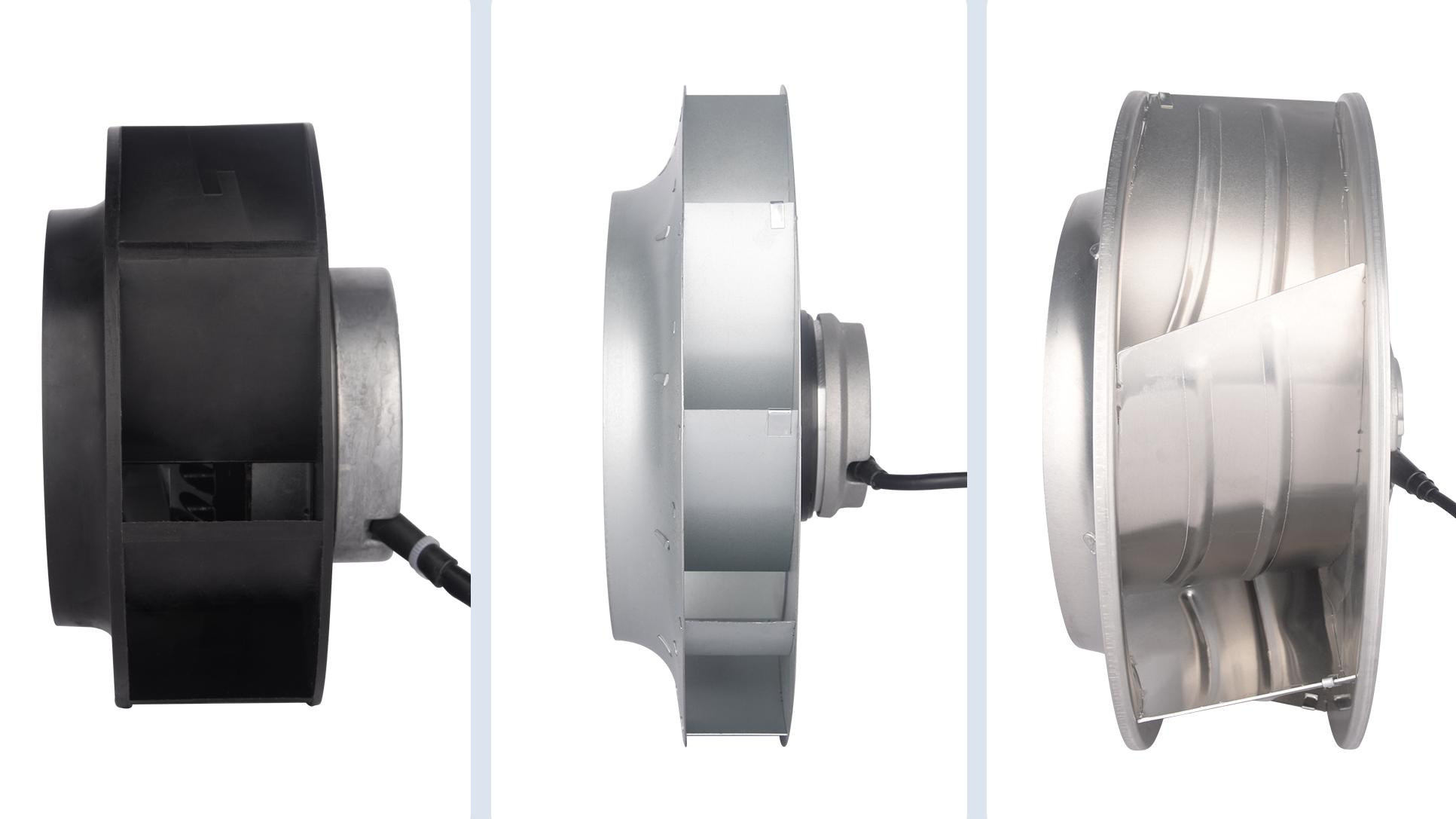

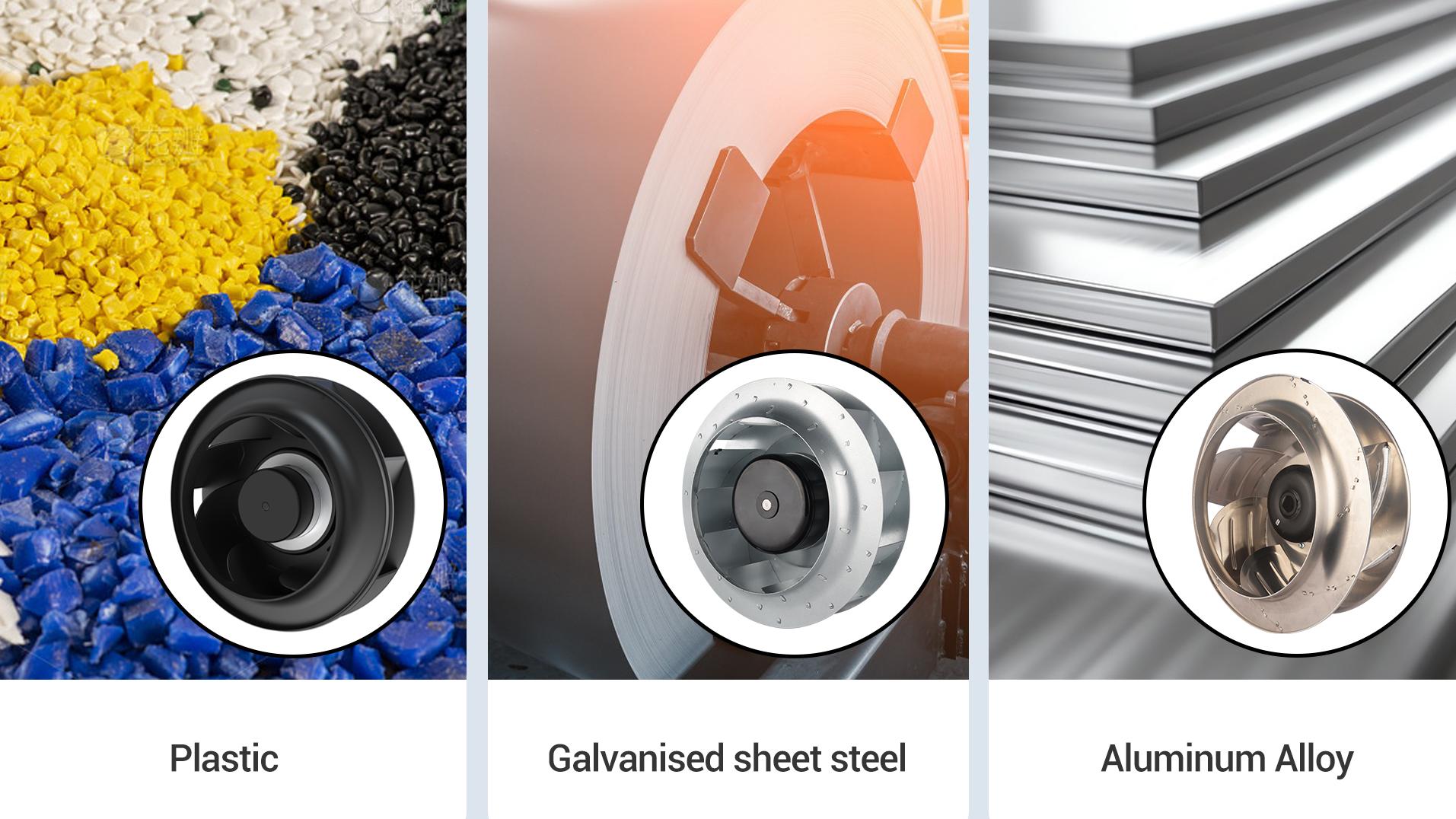

Factories and other places have different needs. Each job site is not the same. LONGWELL lets you pick fans that fit your needs. You can choose from many sizes, blade shapes, and materials. This helps you fix problems like small spaces, hot areas, or loud noise.

Small spaces need fans that are compact, like forward-curved types.

Hot places need fans with heat protection, such as insulation or heat spinners.

Some areas need quiet fans, so you can pick backward-curved blades or covers that lower noise.

Air quality matters for your fan choice. LONGWELL has custom blades and filters for dusty or clean air.

Experts help you find the best balance between cost and how well the fan works, so you save money faster.

LONGWELL’s OEM and ODM services let you order fans made just for your job. You can pick anti-rust coatings, metals that do not corrode, or special blade shapes. These choices help you deal with chemicals, dust, or high heat. You also get fans that are safe for places with explosions or harsh conditions.

LONGWELL Fan Benefits

LONGWELL is a good choice for factories because it has many fans and strong support. You can pick from over 20,000 fan models. You get samples in 1-3 days and big orders in 15-30 days. LONGWELL has top certifications like ISO9001, CE, and UL/ETL, so you know the fans are good.

Feature | LONGWELL Fans |

|---|---|

Up to 90% (EC motors) | |

Product Range | 20,000+ models |

Certifications | ISO9001, CE, UL/ETL, FCC, etc. |

Delivery | Samples: 1-3 days; Bulk: 15-30 days |

Support | Global technical assistance |

You also get help from LONGWELL’s offices and technical teams around the world. This support helps your factory work well. LONGWELL’s fans work in tough places and help you use less energy. You can trust LONGWELL to give you strong and reliable fans for any job.

Centrifugal fans let you manage air flow, temperature, and air quality in HVAC and industrial systems.

They give steady air movement and strong pressure for different jobs.

These fans take out old air, bring in new air, and help keep your space safe.

LONGWELL offers advanced and dependable fans with quick help and lots of options.

Want better ventilation? Reach out to LONGWELL for expert help and custom solutions.

FAQ

What makes centrifugal fans important for HVAC systems?

You get steady airflow and strong pressure from centrifugal fans. These fans help your HVAC system move air through long ducts and filters. You can keep your indoor air clean and comfortable with the right fan.

Can I use centrifugal fans in clean rooms?

Yes, you can use centrifugal fans in clean rooms. These fans help control air quality and remove tiny particles. You keep your space safe for sensitive work, like labs or electronics assembly.

How do data center centrifugal fans help with cooling?

You use data center centrifugal fans to move large amounts of air. These fans keep your servers cool and prevent overheating. You protect your equipment and keep your data center running smoothly.

What should I consider when choosing an industrial fan?

You should look at airflow needs, pressure, noise, and space. You also need to think about the environment, like heat or chemicals. LONGWELL offers many options to fit your specific requirements.

See Also

Selecting The Best Centrifugal Fan For Your Needs 2025

Key Industrial Blower Fan Innovations Manufacturers Must Understand

A Guide To Picking The Perfect Cross Flow Fan