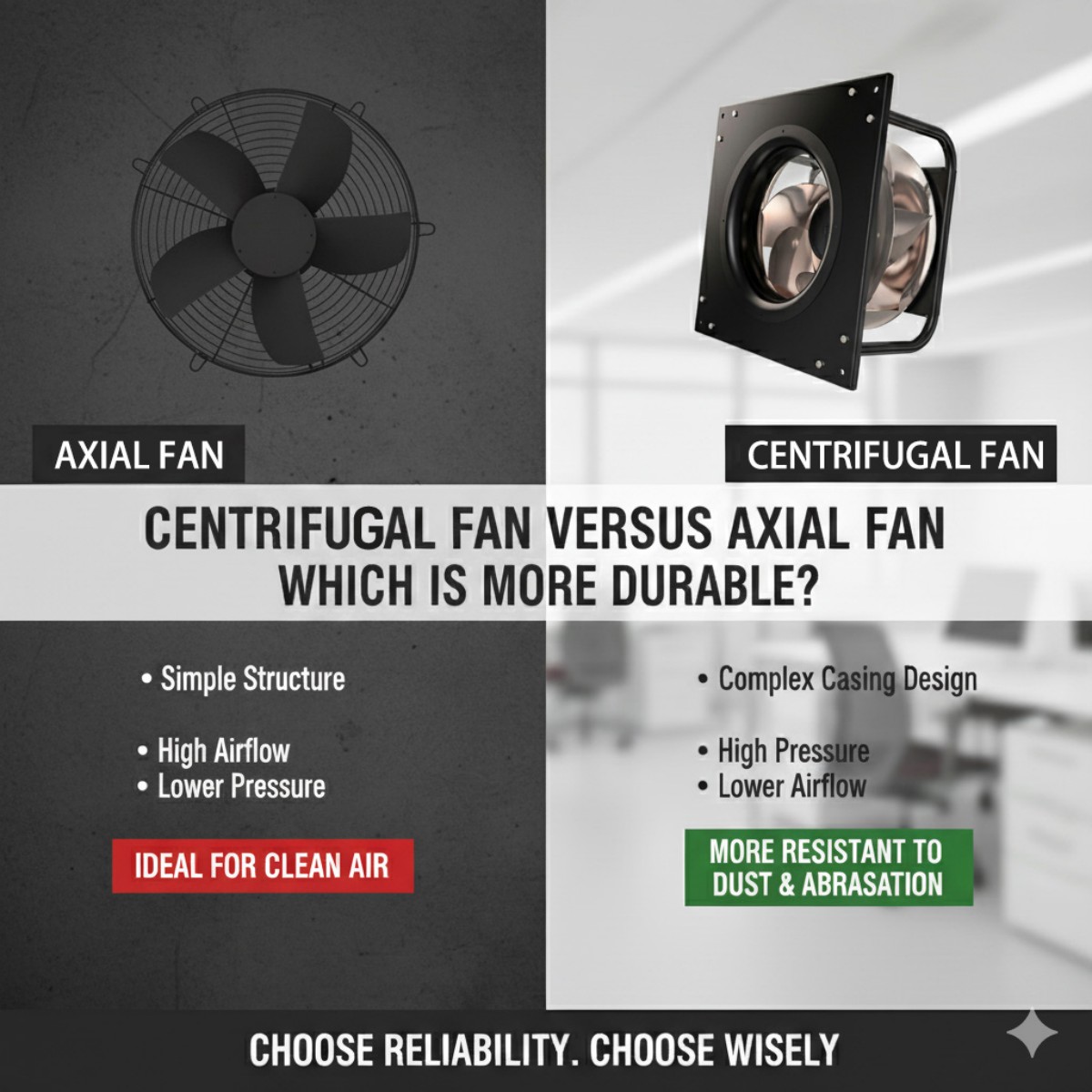

Centrifugal Fan Versus Axial Fan Which Is More Durable

If you want a fan with a long lifespan, you should consider a centrifugal fan. Most centrifugal fans last between 15 and 20 years, while an axial fan usually runs for 10 to 15 years.

DC centrifugal fans can operate for 50,000–70,000 hours.

Centrifugal fans have a sturdy, enclosed design. Their blades stay protected from debris and high temperatures.

Axial fans have open blades, so they are easier to clean but can get damaged more easily.

How you use and maintain your fan will affect how long it lasts.

Key Takeaways

Centrifugal fans work for a long time, often 15-20 years. Their strong design keeps out dust and heat.

Axial fans are simple to clean and fix. They usually last only 10-15 years. These fans are good for light jobs in clean places.

Cleaning and checking for damage helps fans last longer. Both types need regular care to work well.

Pick a centrifugal fan for hard jobs that need strong power. Use an axial fan for easy airflow in clean rooms.

Think about where you will use the fan and how often. This helps you choose the right fan for best results and long life.

Centrifugal Fan vs Axial Fan Design

Centrifugal Fan Construction

A centrifugal fan has a strong and closed design. The blades sit inside a case. This case keeps out dust, dirt, and heat. The fan works well in hard places like factories or kitchens. The blades are made from steel, stainless steel, or aluminum. Steel blades are tough and good for heavy jobs. Stainless steel does not rust, so it lasts longer in wet places. Aluminum blades are light and work best when you do not need much power.

Centrifugal fans have different blade shapes. Forward curved blades are quiet but may wear out faster. Backward inclined blades can handle fast speeds and high pressure. These blades last longer and save energy. Radial blades are very strong and work well for high pressure. But they can be loud.

Tip: For tough jobs, pick a centrifugal fan with backward inclined blades and stainless steel. This will make your fan last longer.

Axial Fan Structure

Axial fans have a simple design. You see open blades on a hub. Air goes straight through the fan. This makes it easy to clean and take care of. Most axial fans use light materials like aluminum. This makes the fan easy to move and put in place. But it may not last long in hard places.

The shape and angle of the blades matter for how long the fan lasts. Aerofoil-shaped blades move air well and do not wear out fast. You can change the blade angle to control airflow. This can help the fan last longer. Longer blades move more air but may wear out faster if used too much.

Note: Axial fans are best for places that need simple airflow and easy cleaning, like offices or homes.

Impact on Durability

How you use and care for your fan changes how long it lasts. Centrifugal fans are strong and last longer because of their closed blades. Axial fans need less care but may not do well in tough places.

Here is a quick comparison:

Fan Type | Durability Characteristics | Maintenance Requirements |

|---|---|---|

Centrifugal fan | Handles tough jobs; lasts 10-15 years if cared for. | Needs regular care, especially in dusty places. |

Axial fan | Lasts 5-10 years; simple design may not last as long. | Needs less care but should be cleaned and checked often. |

Pick a centrifugal fan if you want it to last longer and work in hard places. If you want easy cleaning and light use, choose an axial fan.

To learn more about strong fans, visit LONGWELL’s website at www.longwellfans.com. They have many centrifugal and axial fans for different needs.

Fan Lifespan Comparison

Centrifugal Fan Lifespan

When you choose a centrifugal fan, you get a machine built for a long service life. Most centrifugal fans in factories and large buildings last between 15 and 20 years. The strong case and sturdy blades help protect the fan from dust, heat, and damage. You can use these fans in places with high pressure and tough conditions. The design helps the fan work for many years without breaking down.

Centrifugal fans often use steel or stainless steel blades. These materials resist rust and wear.

The closed housing keeps out dirt and moisture, which helps extend the service life.

You can expect a centrifugal fan to keep working even when the air is dirty or hot.

If you want a fan that lasts a long time, a centrifugal fan is a smart choice. Many companies trust these fans for heavy-duty jobs. LONGWELL offers centrifugal fans designed for long service life. You can find more details at www.longwellfans.com.

Axial Fans Lifespan

Axial fans have a simpler structure. You see the blades and hub, and air moves straight through. Most axial fans last about 10 to 15 years. The open design makes cleaning easy, but the blades can get damaged faster. If you use axial fans in clean places like offices or homes, you can expect a good service life.

Axial fans work best in places with low pressure and clean air.

The simple design means fewer parts can break, but the blades need regular checks.

With good care and quality materials, some axial fans can last much longer.

You can make the service life of axial fans even longer by cleaning them often and checking for loose parts. In some cases, industrial fans with strong construction and regular maintenance can last up to 50 years. LONGWELL provides axial fans for many uses, and you can learn more at www.longwellfans.com.

Real-World Data

You may wonder how these numbers look in real life. Here is a quick table to help you compare the service life of centrifugal fans and axial fans:

Fan Type | Average Service Life | Best Use Cases | Extra Notes |

|---|---|---|---|

Centrifugal fan | 15-20 years | Factories, kitchens | Handles tough jobs, needs care |

Axial fans | 10-15 years | Offices, homes | Easy to clean, check blades often |

Tip: You can extend the service life of both fan types by installing them correctly and keeping them clean.

Sometimes, axial fans last longer than expected. If you use high-quality parts and take care of the fan, you may see a service life of up to 50 years. This is rare, but it shows how important maintenance is. The simpler structure of axial fans means fewer things can go wrong, but you need to watch for blade damage.

If you want a fan with a long service life, think about where you will use it and how much care you can give. Centrifugal fans work best in tough places. Axial fans are great for easy jobs and clean air.

Maintenance and Failure Points

Centrifugal Fan Maintenance

You need to keep your centrifugal fan in good shape to get the most out of its reliability. Regular checks help you spot problems early. Here are some important tasks you should do:

Inspect the fan housing for cracks or corrosion.

Check the blades for damage or bending.

Make sure belts and pulleys have the right tension and are not worn out.

Clean the fan inlet and outlet so air can flow easily.

Verify that electrical connections are tight and free from rust.

Lubricate bearings to keep the fan running smoothly.

Perform vibration analysis to catch issues before they get worse.

Tip: LONGWELL offers fans that are easy to maintain. You can find more information at www.longwellfans.com.

Axial Fan Maintenance

Axial fans need less work, but you still have to care for them to keep their reliability high. Cleaning and simple checks go a long way. Here is what you should do:

Clean the blades and housing often to stop dust from building up.

Inspect for wear, damage, or imbalance.

Lubricate bearings and motors as the manufacturer suggests.

Check belt tension and alignment.

Make sure the motor gets the right power and works well.

Note: Regular cleaning helps axial fans last longer and keeps airflow strong.

Common Issues

Both fan types can run into problems that affect how long they last. You should know what to look for. Here is a table showing common failure points and what causes them:

Failure Point | Causes |

|---|---|

Imbalance | Bent blades, stuck particles, poor balancing, heat damage |

Misalignment | Bad setup, loose parts, worn belts or pulleys |

Bent Shaft | Heavy loads, sudden shocks, too much force |

Structural Issues | Weak base, moving ground, broken bolts, wrong design |

Bearing Problems | Not enough oil, poor assembly, low-quality parts, damage from misalignment |

If you check your fan often and fix small problems, you can boost reliability and make your fan last longer.

Factors Affecting Durability

Installation Quality

It is important to install your fan the right way. If you do not set up the shaft system well, the fan can shake. Bad connections can make the fan vibrate too much. Vibrations can hurt the bearings and couplings. You might notice problems with how the fan follows controls. If the fan does not match signals from the control room, it may not work right. Careful installation helps your fan run smoothly and last longer.

Tip: Always use the manufacturer’s instructions when installing your fan. LONGWELL has helpful guides for all their fans at www.longwellfans.com.

Operating Environment

Where you use your fan changes how long it lasts. Some places are harder on fans than others. Look at this table to see how different things affect the lifespan of centrifugal and axial fans:

Environmental Factor | Impact on Lifespan |

|---|---|

Ambient Temperature | High temperatures make fans wear out faster and oil break down. |

Dust Accumulation | Dust can wear out bearings, change weight, and block heat, so fans do not last as long. |

Operating Conditions | Bad service places make fans run faster and harder, so they wear out sooner. |

If your fan is in a dusty or hot place, clean and check it more often. Some fans, like ones made from titanium or FRP, work better with gases or sticky dust. For example, Covent Type E fans have backward-inclined blades that help stop stuff from sticking. Picking the right fan for your place saves energy and helps your fan last longer.

Usage Patterns

How you use your fan matters a lot. If you run your fan fast all the time, it will wear out quicker. Using it nonstop puts more stress on the parts. If you use your fan only when needed, it can last much longer. Turning it off sometimes lets the fan cool down and rest. This helps centrifugal and axial fans stay in good shape.

Note: Using your fan wisely makes it last longer and saves energy in your building.

Choosing the Right Fan

Application Needs

You should pick a fan that fits your needs. First, think about what your system needs. Axial fans are good for cooling offices or homes. They move air straight and fit in small spaces. You can use them for simple cooling or ventilation. Centrifugal fans are better for places that need steady airflow and high reliability. These fans push air with high pressure. They work best in factories, kitchens, or tough places.

Here is a table to help you compare the main points for each fan type:

Criteria | Axial Fans | Centrifugal Fans |

|---|---|---|

Design | Small and light | Closed, scroll-shaped case |

Airflow Direction | Along the axis | Across the rotor’s axis |

Pressure Capabilities | Low pressure, lots of air | High pressure, steady air |

Efficiency | Good for low-pressure jobs | Better for steady airflow |

Noise Levels | Quieter | Can be louder |

Applications | Cooling, ventilation | Reliable, high-pressure jobs |

When you pick a fan, check your airflow and pressure needs. Follow these steps:

Find out how much air and pressure your system needs.

Look at fan charts to see if the fan works for you.

Choose the right fan type for your job. Axial fans are good for cooling. Centrifugal fans are best for tough jobs.

Tip: LONGWELL has both fan types for many uses. Go to www.longwellfans.com to find the best fan for you.

Cost vs Longevity

You want a fan that fits your budget and lasts long. Centrifugal fans cost more at first but last longer in hard places. Axial fans cost less and need less care. If you use your fan in clean areas, axial fans save money. Centrifugal fans are very reliable, but you pay more for energy and upkeep.

Here is a table to show the cost differences:

Fan Type | Initial Cost | Lifespan (hours) | Long-term Costs | Energy Efficiency | Maintenance Requirements |

|---|---|---|---|---|---|

Centrifugal | More | 15,000-25,000 | More | Less efficient | Needs more care |

Axial | Less | 20,000-30,000 | Less | More efficient | Needs less care |

Experts say you should pick centrifugal fans for tough places or when you need high reliability. Axial fans are best if you want quiet fans and lower costs. Here is a quick guide:

Scenario | Recommended Fan Type | Reason |

|---|---|---|

Dusty or wet places | Centrifugal Fan | Closed case keeps out dirt and water |

Small budget | Axial Fan | Cheaper and easy to buy |

High pressure needs | Centrifugal Fan | Handles pressure better |

Quiet places | Axial Fan | Makes less noise |

Always running | Centrifugal Fan | Strong build for high reliability |

Note: You can get help from LONGWELL to balance cost and durability. Their website, www.longwellfans.com, has guides and product info.

Centrifugal fans last longer in tough places because of their strong design and resistance to dust and moisture. Axial fans work well for simple jobs but do not handle harsh conditions as well. You should look at your needs, the environment, and how much care you can give.

Fan Type | Durability | Best Use Case |

|---|---|---|

Centrifugal | High | Factories, kitchens |

Axial | Medium | Offices, homes |

If you want the best value, balance cost with how long the fan will last. For more options, visit LONGWELL at www.longwellfans.com.

FAQ

How do you choose between a centrifugal fan and an axial fan?

You should look at your needs. Centrifugal fans work best for tough jobs. Axial fans fit simple spaces. LONGWELL offers both types. Visit www.longwellfans.com for help.

What maintenance helps fans last longer?

You should clean blades, check for damage, and lubricate moving parts. Regular checks keep fans running well. LONGWELL fans come with easy care guides.

Can you use axial fans in dusty places?

Axial fans do not handle dust well. Dust can damage open blades. You should pick centrifugal fans for dusty areas. LONGWELL has strong options for harsh environments.

Which fan is quieter?

Axial fans usually make less noise. You can use them in offices or homes. Centrifugal fans may sound louder in heavy jobs. LONGWELL lists noise levels for each model.

Where can you find more information about fan durability?

You can visit LONGWELL’s website at www.longwellfans.com. The site has guides, product details, and tips for choosing durable fans.

See Also

Selecting The Ideal Fan Type For Your Unique Space

Guidelines For Picking The Perfect Axial Fan In 2025

The Importance Of Axial Fans In Cooling Machinery