EC Backward Curved vs Forward Curved Centrifugal Fans Which Performs Better

Backward curved fans usually work better than forward curved fans in tough jobs. They are more efficient, especially when there is high pressure. This is because of their special blade shape and strong build. New data shows backward curved fans keep airflow even with resistance. Forward curved fans are good at moving lots of air in low-pressure places. They are also quieter. EC backward curved centrifugal fans are best for factories. Forward curved fans are better for homes and offices. You should pick a centrifugal fan based on airflow, pressure, and noise needs.

Key Takeaways

EC backward curved fans use less energy and work better when pressure is high. Forward curved fans move a lot of air quietly. They work best in places with low pressure, like homes and offices. Backward curved fans last longer and need less fixing. This makes them good for hard jobs in factories. You and saving money over time. EC backward curved fans help lower energy bills. They also help the environment in big buildings.

Performance Differences

Efficiency

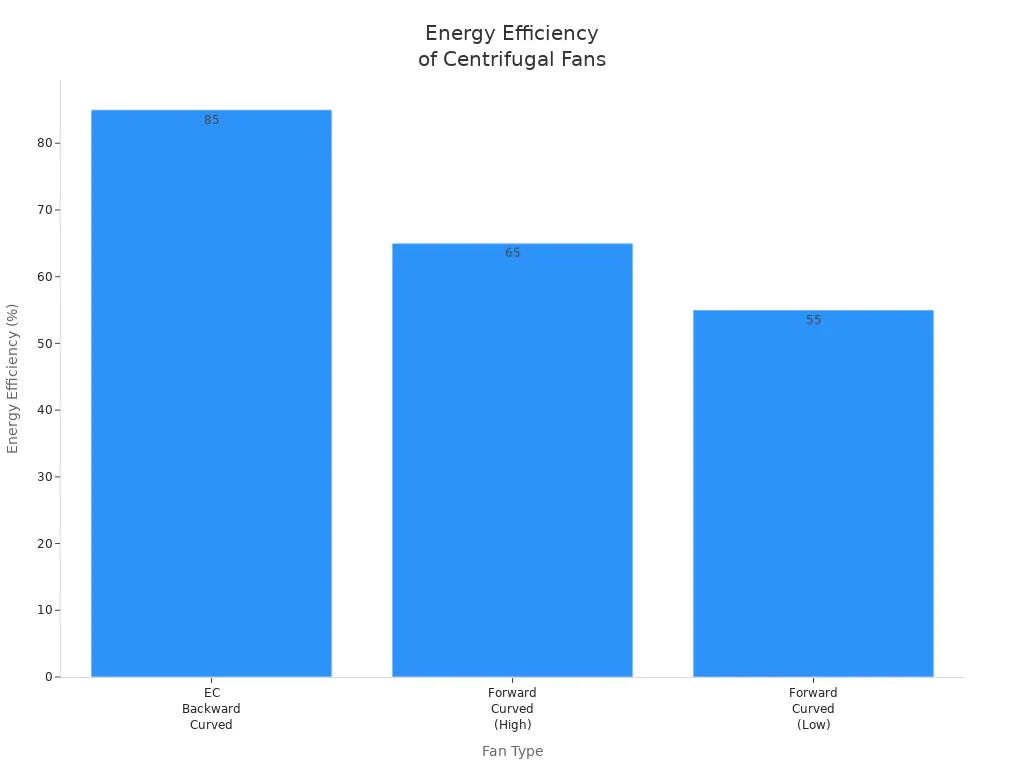

EC backward curved centrifugal fans are very good at saving energy. These fans use special EC motors. The motors help control speed and waste less energy. Tests show backward curved fans can be up to 85% efficient. Forward curved fans are only about 55% to 65% efficient. The blades on backward curved fans help air move smoothly. This means less energy is lost. Forward curved fans, even with EC motors, are not as efficient. Backward curved fans work better when the job is hard.

Fan Type | Energy Efficiency | Performance Characteristics |

|---|---|---|

EC Backward Curved Fans | Up to 85% (higher) | Reduced turbulence, smoother airflow, better static pressure, precise speed control with EC motors |

Forward Curved Fans | Typically 55% to 65% | Less efficient, especially in high-pressure applications, suited for low-pressure systems |

EC backward curved centrifugal fans can change speed when needed. This helps the fans save energy and lower costs. Forward curved fans with EC motors are a little better, but their design still uses more energy. In places like factories, backward curved fans save more energy than forward curved fans.

Airflow and Pressure

Airflow and pressure are important when picking a fan. Backward curved fans are best for jobs that need high pressure. These fans keep moving air even when it gets harder. They are great for factories and HVAC systems with filters or long ducts. For example, a 220mm EC backward curved fan can reach up to 950 Pa. It handles high pressure easily.

Feature | Forward Curved Centrifugal Fans | EC Backward Curved Centrifugal Fans |

|---|---|---|

Airflow Rate | Higher airflow capacity, suitable for large volumes of air at relatively low pressure | Generally lower airflow rates compared to forward curved fans |

Static Pressure Capability | Limited static pressure capabilities | Superior static pressure capabilities, ideal for overcoming resistance and pressure drops |

Efficiency | Lower efficiency compared to backward curved fans | Higher efficiency due to blade design and better airflow control |

Noise Level | Operate at lower noise levels | Tend to be noisier, though newer designs have improved noise performance |

Cost | More cost-effective initially | Higher upfront cost but better long-term energy savings |

Application Suitability | Suitable for applications prioritizing high airflow at low pressure | Better suited for HVAC systems requiring higher static pressure and precise airflow control |

Forward curved fans move lots of air at low pressure. They are best for homes or offices. These fans lose power when pressure goes up. Backward curved fans keep working well even when pressure is high. They give steady airflow and control.

Noise Levels

Noise is important when choosing a fan for quiet places. Forward curved fans are quieter because of their blade shape. These fans do not need extra noise control. They are good for offices, homes, and quiet rooms.

Fan Type | Noise Characteristics | Noise Reduction Technologies / Considerations |

|---|---|---|

Forward Curved Fans | Operate at lower noise levels due to blade design that minimizes turbulence | Naturally quieter by design; suitable for noise-sensitive environments without extensive additional noise reduction technology |

Backward Curved Fans | Tend to produce higher noise levels because of larger blades and higher airflow capacity, increasing turbulence and noise | Require additional design improvements and advanced technologies to reduce noise; newer models have incorporated quieter designs to mitigate noise disadvantages |

Backward curved fans are louder, especially when moving lots of air or working at high pressure. New EC motors and better blade shapes help make these fans quieter. EC motors run quietly and can change speed to lower noise. New backward curved fans are now quieter and can be used in more places.

Note: When picking centrifugal fans, think about airflow, pressure, and noise. Backward curved fans work best for hard jobs. Forward curved fans are quieter and good for easy jobs.

Application Comparison

Backward Curved Fans

Backward curved fans are best for tough jobs in factories. These fans work well and keep moving air, even when pressure is high. Many industries use EC backward curved centrifugal fans because they handle hard work. Their design helps save energy and lets you control speed. They are also strong and last a long time.

Key Performance Metrics Prioritized | |

|---|---|

Hygienic HVAC Systems | High efficiency, low noise, precise airflow control, enhanced static pressure |

Chemical and Petrochemical | Corrosion resistance, high pressure range, stainless steel impellers |

Mining | Robustness against particulate ingress, high pressure range, durable materials |

Oil and Gas | Compliance with safety standards, explosion-proof variants, reliability |

Power Generation | High operational continuity, inline mounting, integration with equipment suppliers |

Filtration Setups | Resistance to corrosive gases and particulates, compact footprint |

All Sectors | Energy efficiency, noise reduction, IoT integration for predictive maintenance |

Backward curved fans do better than forward curved fans when pressure is high. They keep moving air, even if it gets harder. These fans use brushless EC motors, so they need less fixing and last longer. Many places like factories, cleanrooms, and data centers pick backward curved fans. They want strong fans that save energy. Safety is important too. These fans stop the motor from getting too hot and meet rules like CE and UL.

Tip: Use backward curved fans where you need strong pressure, energy savings, and fans that last a long time.

Forward Curved Fans

Forward curved fans are great for places that need lots of air but not much pressure. Their curved blades help move air smoothly. This makes them good for stores, homes, and offices. These fans run slower, so they are quieter and use less energy.

Forward curved fans are good for HVAC in offices, homes, and stores.

They give steady air for cooling and fresh air in big buildings.

Their design helps save money and makes them last longer.

These fans are easy to take care of and can fit different needs.

Forward curved fans are quieter than backward curved fans. This makes them good for places where noise matters. They do not work as well when pressure is high, but they are great for most jobs with low pressure. Many building managers use forward curved fans in air units. They want smooth and quiet air.

Note: Forward curved fans are a good choice if you want quiet, low-cost fans that move lots of air in places with low pressure.

Energy and Cost

Power Usage

How much energy a fan uses is very important. EC backward curved fans use less power than forward curved fans. For example, a 220mm EC backward curved fan uses 168W when running all the time. A 200mm EC forward curved fan uses about 230W in the same situation. This means backward curved fans save more energy, especially in big systems.

Model / Series | Diameter Range (mm) | Power Input Range (W) | Application Notes | |

|---|---|---|---|---|

EC Backward Curved Centrifugal Fans | LWBE3G EC FAN | 133-250 | 30-750 | General range for smaller sizes |

EC Backward Curved Centrifugal Fans | LWBE3G EC Plenum fan | 280-450 | 170-4200 | Mid to large size, plenum applications |

EC Backward Curved Centrifugal Fans | LWBE3G High Pressure Centrifugal fan | 500-630 | 1250-5600 | High static pressure, industrial use |

Backward curved fans are more efficient and cost less to run over time. They help the environment by using less energy. Forward curved fans use more energy for the same job. This makes them cost more to use and worse for the planet. In big buildings, backward curved fans help companies follow energy rules.

Tip: Using EC backward curved fans in big places saves money and helps the environment.

Maintenance

How often you need to fix a fan changes how much it costs. Backward curved fans are strong and work well in hard places. They do not break easily from dust or bad air. Their blades do not get blocked as much. These fans last longer and keep working even if things change.

Aspect | Backward Curved Centrifugal Fans | Forward Curved Centrifugal Fans |

|---|---|---|

Rugged design, suitable for demanding industrial environments | Less durable, prone to blade clogging in dusty environments | |

Expected Lifespan | Longer lifespan due to operational reliability and robustness | Shorter lifespan due to imbalance and reduced performance risks |

Efficiency | High static efficiency, lower power consumption over lifespan | Less efficient, higher risk of motor overload |

Cost-effectiveness | Higher initial cost but cost-effective over continuous use | Lower initial cost but less cost-effective in harsh conditions |

Forward curved fans cost less at first. But they break down more in tough places. Their blades can get blocked, which can hurt the motor. Over time, these fans may cost more than backward curved fans. Many companies pick backward curved fans to save money and avoid problems.

EC backward curved fans cost more at the start because of their design.

They work better and need less fixing.

Forward curved fans are cheaper at first but may cost more later.

Note: Buying backward curved fans means fewer repairs, longer life, and lower energy bills.

Key Features

To pick the right centrifugal fan, you need to know their main features. EC backward curved centrifugal fans have blades that bend away from how the fan spins. This shape helps them work better and handle higher static pressures. They use ball bearings, so they last longer and need less fixing. These fans do not use much power and stay quiet, even when working hard. Their special blades and EC motors help them save energy and last a long time. They also do well in dusty places because dust does not stick to them easily.

Forward curved centrifugal fans can move more air but only at lower static pressures. These fans are quieter and usually have a scroll housing. They are good for homes and offices where you want lots of air and little noise. But they are not as good in tough places and do not last as long.

Think about pressure, airflow, and how much you need the fan to last before you choose.

Here is a table that shows the main features of both types of fans:

Feature | EC Backward Curved Centrifugal Fans | Forward Curved Centrifugal Fans |

|---|---|---|

Blade Design | Blades curve away from rotation | Blades curve toward rotation |

Efficiency | High (energy-saving, low power use) | Moderate (higher power use) |

Static Pressure Capability | Excellent (handles high resistance) | Limited (best for low resistance) |

Noise Level | Low to moderate (improved with EC motors) | Very low (quiet operation) |

Reliability | High (ball bearings, less maintenance) | Moderate (more maintenance in tough jobs) |

Dust Resistance | Strong (less dust buildup) | Weaker (more dust accumulation) |

Typical Applications | Industrial, commercial, dusty environments | Residential, office, clean air systems |

Housing Requirement | Freewheel (no scroll housing needed) | Needs scroll housing |

Motor Technology | EC motors (precise speed control) | AC or EC motors |

Lifespan | Long (robust design) | Shorter (prone to clogging) |

EC backward curved centrifugal fans work best in hard places.

Forward curved centrifugal fans are quiet and move lots of air in easy jobs.

EC backward curved centrifugal fans work better for tough jobs. These fans save more energy and handle high pressure well. They also last longer than other fans. Forward curved fans are best for quiet places with low pressure. They cost less and are good for homes or offices. The table below shows what to think about when picking a fan:

Factor | Backward Curved Fans | Forward Curved Fans |

|---|---|---|

Airflow Requirements | Precise airflow management | High air circulation |

Pressure Requirements | High pressure, resistance handling | Low pressure, limited resistance |

Noise Considerations | Higher noise, quieter models available | Lower noise, ideal for quiet spaces |

Environmental Conditions | Handles dust, clean air | Best for clean air |

Cost Considerations | Higher initial cost, long-term savings | Lower upfront cost |

Backward curved fans are great for factories, dusty places, or high pressure.

Forward curved fans are better for quiet, clean, and low-pressure rooms.

Each fan type has special benefits for different places.

If you need help picking EC centrifugal fans, ask LONGWELL for advice.

FAQ

What is the main difference between backward curved and forward curved centrifugal fans?

Backward curved fans have blades that bend away from how the fan spins. Forward curved fans have blades that bend toward the spinning direction. This change in blade shape affects how well the fan works, how much pressure it can handle, and how loud it is.

Which fan type lasts longer in industrial environments?

Backward curved centrifugal fans last longer in hard places. Their strong build and dust-resistant design help them work better in tough spots than forward curved fans.

Are EC backward curved fans more energy efficient?

Yes. EC backward curved fans use special motors and blade shapes. They save more energy and cost less to run than forward curved fans.

Where should forward curved fans be used?

Forward curved fans are best for quiet and clean places like homes or offices. They move lots of air at low pressure and make little noise.

Do backward curved fans require more maintenance?

No. Backward curved fans need less fixing. Their design stops dust from building up and helps prevent motor problems, so they last a long time.