What Makes Efficient Axial Fans the Top Choice for Modern Ventilation

You see efficient axial fans for any application as the best choice for modern ventilation. They work very well, make little noise, and fit many places. HVAC professionals pick these fans for saving energy, easy care, and being flexible. The table below lists the main reasons why people like them:

Reason | Description |

|---|---|

Energy Efficiency | These efficient axial fans use less power than others, so they save money. |

Ease of Maintenance | Their simple design makes cleaning and fixing easy. |

Versatility | They work for many jobs, like cooling and exhaust. |

Environmentally Friendly | They use less energy and are quieter, which helps the environment. |

You can pick from many axial fan models and materials to fit your needs. The global HVAC market for these efficient axial fans for any application is growing fast. This means you are making a smart choice for the future. Efficient Axial Fans help you get great results for your ventilation projects.

The global axial fans market may grow about 5.4% each year from 2025 to 2034.

Key Takeaways

Efficient axial fans help save energy and lower costs. They use less power than other fans. This makes them a smart choice for ventilation.

These fans are simple to take care of. Their design lets you clean and fix them quickly. This saves you time and money.

Axial fans are very useful. You can use them for cooling or exhaust. They work well in many places.

Picking the right material is important. Choose fans made from stainless steel or fiberglass for tough places. This keeps them strong and safe.

You can make fans work better with high-efficiency motors and smart controls. This helps save energy and makes airflow better in your area.

Efficient Axial Fans for Any Application

Key Features

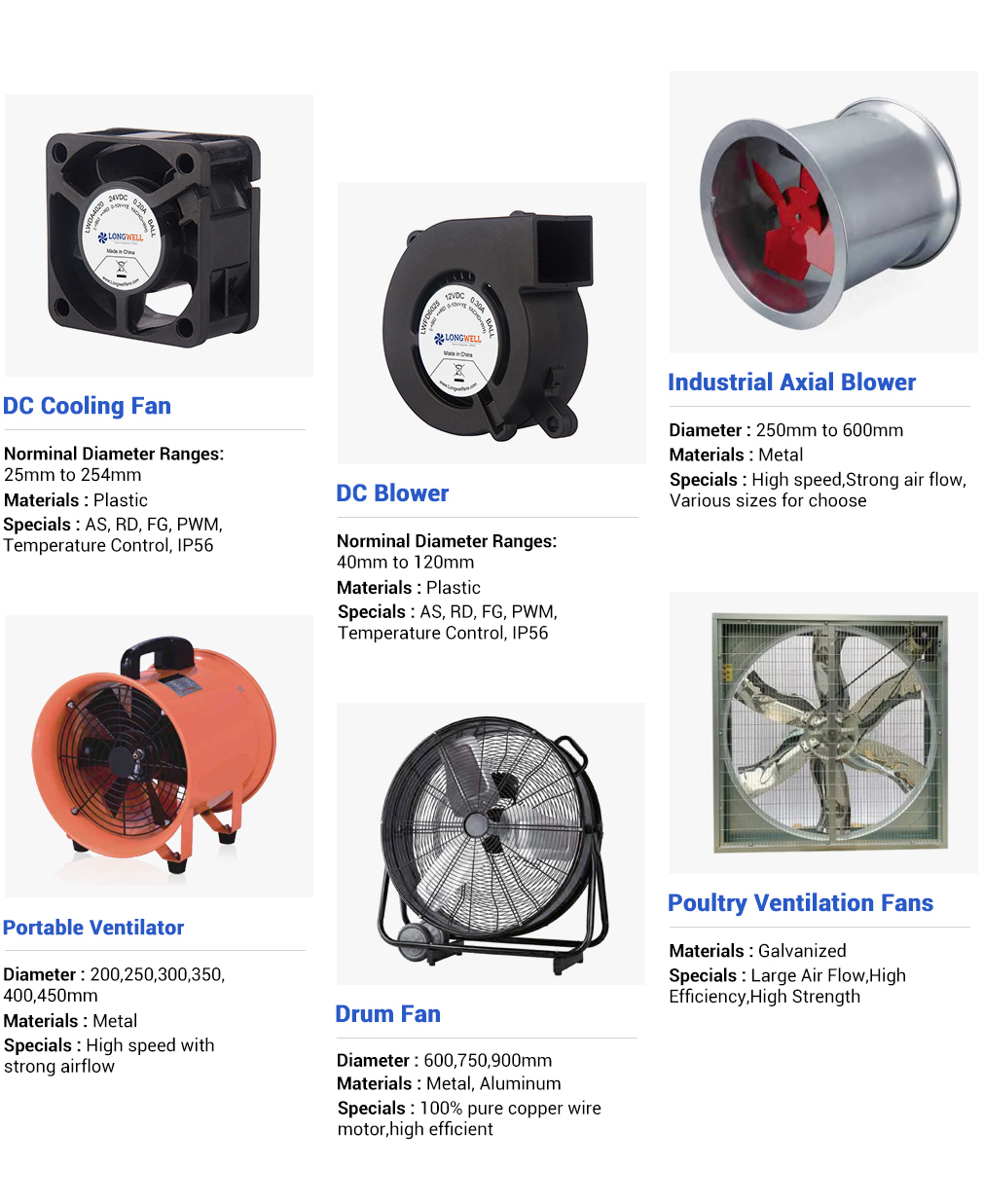

Efficient axial fans give strong airflow and work well. You can use them in many places. They help in warehouses and paint booths. They move air in furnace systems. These fans help with ventilation in pump stations. They remove fumes from welding booths. They keep air moving in kitchens. Auto shops use them to cool machines. You see them in paper mills and textile factories. They are in transportation plants too. These fans cool data centers. They help barns and storage areas have good airflow.

Efficient axial fans are quiet and move a lot of air. You can use them for cooling and exhaust. They help with air circulation. They handle fast airflow and keep workspaces comfy. Axial hvac fans make indoor air better. They lower humidity and spread out pollutants. You get good airflow in big and small spaces.

Manufacturers make fans for your needs. You can pick explosion-proof or corrosion-resistant fans. Some fans have blades you can adjust. This helps you get the airflow you want. You can choose direct or belt drive fans. This makes installing them easy.

Material and Model Options

You have many choices for efficient axial fans. The main materials are mild steel, stainless steel, aluminum, and FRP. Each material has its own benefits:

Material | Advantages | Best Applications |

|---|---|---|

Mild Steel | Strong and cheap, good for normal jobs | HVAC, general ventilation, non-corrosive places |

Stainless Steel | Handles moisture, chemicals, and heat | Food, medicine, marine, chemical plants |

Aluminum | Light, strong, and resists rust | Light fans, blowers, HVAC |

FRP (Fibre-Reinforced Plastic) | Handles tough chemicals, light, not conductive | Chemical plants, wastewater, fume extraction |

Special Coatings | Makes fans last longer, resists damage and wetness | Dusty places, spray booths, drying |

You can pick from different axial fan models. AC axial fans are good for hard jobs and run all the time. DC axial fans save energy and let you change speed. This helps you use less power. EC axial fans mix the best parts of AC and DC fans. They are efficient and quiet. They are great for places that need careful airflow.

Manufacturers help you with advice and custom fans. You can work with them to design fans for your needs. This makes sure your space gets the best air and cooling.

Axial Fan Efficiency Explained

How Axial Fans Work

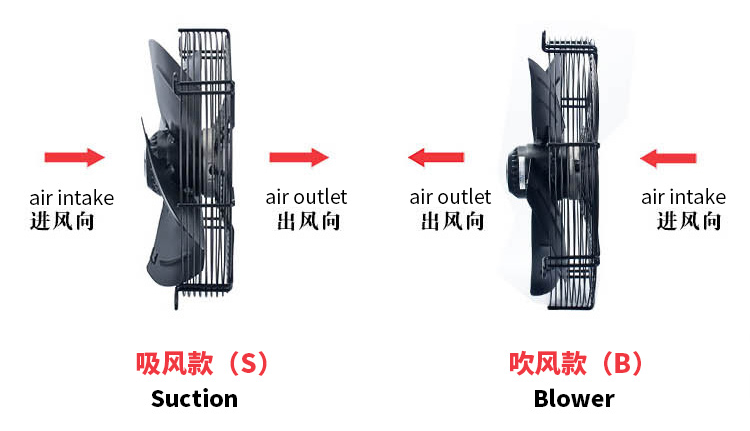

Axial fans are used in many places. They move air in a straight line. The air goes the same way as the fan’s shaft. This makes strong airflow and helps air move fast. The blades spin around the middle part. They pull air in from one side. Then, they push air out the other side. This design lets you move lots of air with less work.

Here is a table that shows how axial fans and radial fans are different:

Feature | Axial Fans | Radial Fans |

|---|---|---|

Airflow Direction | Moves air parallel to the shaft | Redirects air radially outward |

Pressure Generation | High-volume, low-pressure airflow | High-pressure airflow |

Efficiency and Noise | Efficient at low static pressures, higher noise | Efficient at high pressures, generally quieter |

Applications | Ventilation, cooling, HVAC, computer cooling | Air handling, industrial processes |

Axial fans are good when you need strong airflow. You see them in factories, kitchens, and data centers. Their design is great for moving air in open spaces. They also work well in ducts with little resistance.

Design for High Efficiency

How well an axial fan works depends on its blades. The shape, angle, and structure matter a lot. Airfoil-shaped blades help air move better and save energy. These blades cut through air easily and push it forward. The angle of the blades is important too. Steeper angles move more air. But they can use more energy and make more noise.

Blade shape changes how air and pressure move.

Airfoil blades move air well along the shaft.

Steeper blade angles move more air but can be louder and use more energy.

Modern axial fans use new technology to work better. New blade shapes help fans work even if air is not perfect. Fewer blades can make less noise but still work well. Makers use 3D printing to test new blade shapes fast. They use computers to find the best design for each job.

High-efficiency axial fans can save a lot of energy. Some fans, like ECplus and Vplus, save over 80% energy compared to old fans. This means you pay less for power and help the planet.

Axial fans are also quiet. They are quieter than centrifugal fans at low speeds. The size and speed of the fan change how loud it is. Bigger fans can move the same air as small ones but are quieter.

Axial fans work in many temperatures. Standard fans work from -20°C to 60°C. Special fans can work in places as hot as 200°C or even 400°C. This means you can use them in tough places like factories, kitchens, and chemical plants.

Tip: Always pick an axial fan with the right temperature rating. This keeps your system safe and working well.

Here is a table that shows how much heat different fans can handle:

Fan Type | Maximum Temperature Tolerance |

|---|---|

Standard Axial Fans | -20°C to 60°C |

Specialized High-Temperature | Up to 200°C or 400°C |

You get many benefits from these features. Axial fans give strong airflow, low noise, and work well. If you pick the right model, you get the best results for your ventilation.

Advantages of Using Axial HVAC Fans

Performance Benefits

Axial hvac fans give you many good things for your building. These fans work very well and use less energy. They move a lot of air but do not need much power. This helps you save money on your energy bills. You can use them in factories and stores.

Here is a table that shows the main performance benefits of using axial hvac fans:

Benefit | Description |

|---|---|

Energy Efficiency | Axial fans consume less power, leading to lower operational costs. |

High Airflow Capacity | They are suitable for applications requiring significant air movement. |

Reduced Maintenance Costs | Fewer repairs and replacements save money over time. |

Axial hvac fans help make the air inside better. They move air around and help clean out bad stuff. This makes the air safer for people. These fans also help keep the room cool and not too wet. People feel good and work better when the air is nice.

Axial hvac fans move air and help clean out bad stuff.

Good airflow helps people feel happy and comfy.

Fresh air fans bring in new air from outside.

They help keep the room cool and not too wet.

These fans help protect people from dirty air inside. Good fans help everyone stay safe and healthy in the building.

Comparison with Other Fan Types

Axial hvac fans are different from other fans like centrifugal fans. Axial fans push air straight ahead. This is good for big rooms and cooling. Centrifugal fans push air out to the sides. They work best when you need strong air pressure, like in dust removal.

Here is a table that compares the two main fan types:

Fan Type | Airflow Direction | Pressure Characteristics | Suitable Applications |

|---|---|---|---|

Axial Fans | Linear, parallel | Low pressure | Cooling components, ventilating spaces |

Centrifugal Fans | Radial, directional | High pressure | Air conditioning, industrial ventilation |

Axial hvac fans move lots of air but do not make much pressure. This is good for mixing air in big places like warehouses. Centrifugal fans make strong pressure but move less air. They are better for small jobs.

Axial hvac fans can move more air than centrifugal fans. For example:

Fan Type | Airflow Capacity (CFM) | Pressure (inwg) | Applications |

|---|---|---|---|

Axial Fans | Up to 5,000 | 0.5 | Cooling electronic appliances, ventilation, AC |

Centrifugal Fans | Up to 1,000 | Up to 10 | Furnaces, industrial air handling, dust removal |

Axial hvac fans are easy to put in. They are small and fit in tight spots. You can install them fast because they have fewer parts. This means you do not spend much time or money fixing them.

Axial hvac fans move lots of air and use little power.

Their small size is good for places with not much room.

Simple design makes them easy to install and fix.

Axial hvac fans give you strong airflow, save energy, and are easy to use. These things make them a great choice for new buildings and old ones.

Tip: Pick strong axial hvac fans for your next project. You will get better air, save money, and make your building nicer.

Choosing the Right Axial Fan

Application Considerations

When you pick axial hvac fans, you must think about a few things. First, check how big your space is. Bigger spaces need more airflow than small ones. Look at how your system is set up. A good setup helps stop hot spots and keeps air cool everywhere. Think about what you need the fan for. Some places just need fresh air. Others need fans for special jobs or ducted systems. You can put axial hvac fans on the wall, in ducts, or use them as portable fans. Always check how much airflow and pressure your system needs. Use fan charts to help you pick the best axial fan for your hvac system.

The place where you use the fan matters a lot. If your space is hot, wet, or has chemicals, you need special materials. The table below shows which materials are best for each condition:

Environmental Condition | Recommended Material |

|---|---|

High temperatures | Stainless steel |

Corrosive environments | Stainless steel, fiberglass |

Humid environments | Stainless steel, aluminum alloys |

Chemical exposure | Specialized coatings, fiberglass |

Low temperatures | Fiberglass (FRP) |

Maximizing Efficiency

You can make your axial hvac fans work better by following some tips. Use high-efficiency motors like EC motors to save energy. Pick the right fan size and blade shape for your system. Change the blade angle and use speed controls to get the airflow you want.

Keep your ducts smooth and straight to help air move easily. Smart controls let you turn fans on only when needed. This saves power. Take care of your fans by cleaning and checking them often. Oil moving parts to keep your fans working well.

Pick the right fan type and material for your job. For example, use corrosion-resistant fans in chemical plants. Use stainless steel fans in food factories. Always look for certifications like AMCA or ANSI to make sure your fans are good quality.

Tip: The right axial hvac fans help your building have better air, cooling, and comfort.

Efficient axial fans move a lot of air and are quiet. You can use them for cooling, ventilation, or making air better. These fans work in homes, factories, and green buildings. The table below shows how they help in different ways:

Application | Benefit |

|---|---|

Ventilation | Brings in fresh air, removes stale aird |

Cooling | Keeps machines and rooms at safe temperatures |

Exhaust Systems | Clears smoke, fumes, and odors |

Energy Efficiency | Saves power with smart speed controls |

You should think about how much air you need. Check the pressure and your environment too before picking a fan. Ask experts or manufacturers to help you find the best fan for your space.

FAQ

What is the main advantage of using an axial fan?

You get high airflow with low energy use. Axial fans move air in a straight line. This design helps you save power and keeps your space well-ventilated.

Can you use axial fans in harsh environments?

Yes, you can. Choose fans made from stainless steel or fiberglass for places with chemicals, moisture, or high temperatures. These materials help your fan last longer and work safely.

How do you choose the right size axial fan?

First, measure your room or area. Check how much air you need to move, called CFM (cubic feet per minute). Use fan charts or ask a manufacturer for help to match your needs.

Are axial fans noisy?

Most efficient axial fans run quietly. Many models produce noise levels as low as 25dB. You can use them in offices, factories, or homes without disturbing people.

What maintenance do axial fans need?

You should clean the blades and check for dust. Oil moving parts if needed. Inspect the fan regularly to keep it running well and to prevent problems.

See Also

A Comprehensive Guide to Axial HVAC Fans Today

Selecting the Perfect Axial Fan for 2025 Applications

The Importance of Axial Fans in Cooling Machinery