Essential Guide to Using Forward Curved Centrifugal Fans in Modern HVAC Systems

You use forward curved centrifugal fans to push air in your hvac and ventilation system. These fans have a special blade shape. This helps them move a lot of air easily and quietly. Their design is sometimes called a squirrel cage. It gives the best airflow for the fan’s size and speed. New changes use lighter materials and better shapes. Some even have AI-powered monitoring. You get quieter fans, better efficiency, and longer fan life. These new features make these fans important for modern air systems.

Key Takeaways

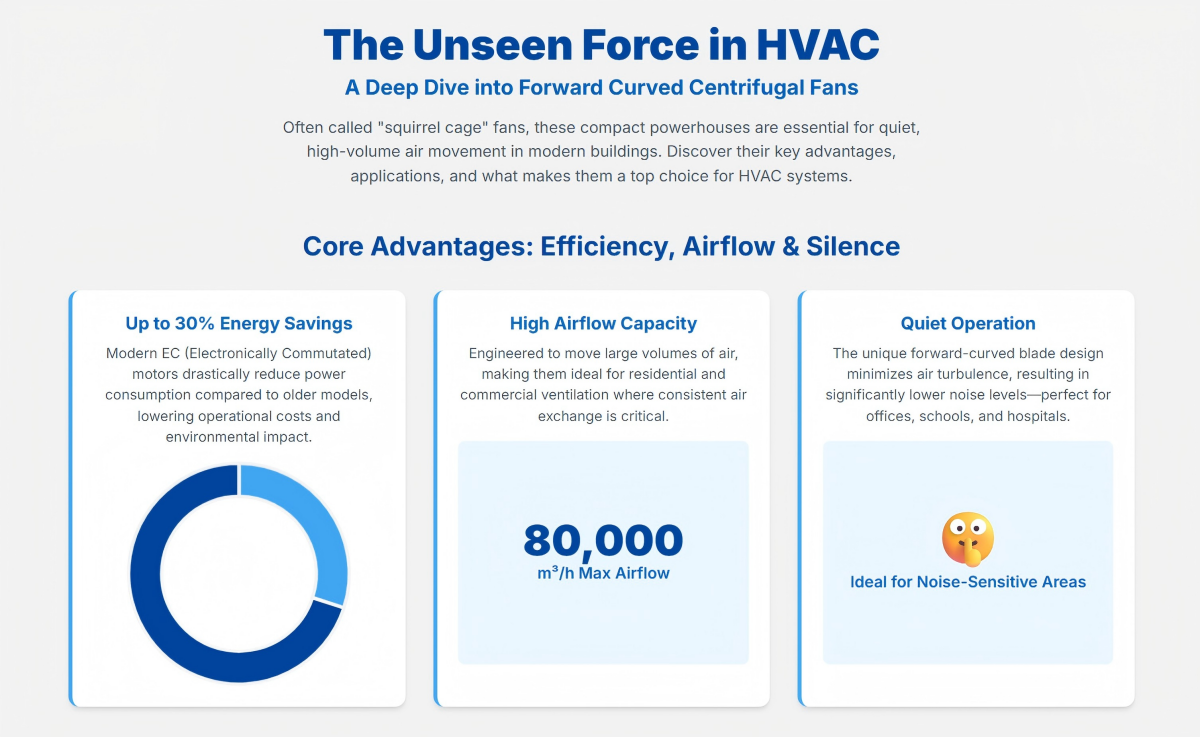

Forward curved centrifugal fans push a lot of air quietly. They work best at low or medium pressure. This makes them great for homes, offices, and schools.

These fans have special blades and a small design. This helps them make less noise. They also fit well in tight spaces. This helps make rooms calm and comfortable.

Fans with new motors and smart features use less energy. They can save up to 30% energy. This lowers costs and helps the fan last longer.

Cleaning and taking care of the fans often keeps them working well. It also makes them quieter. This stops problems like shaking or weak airflow.

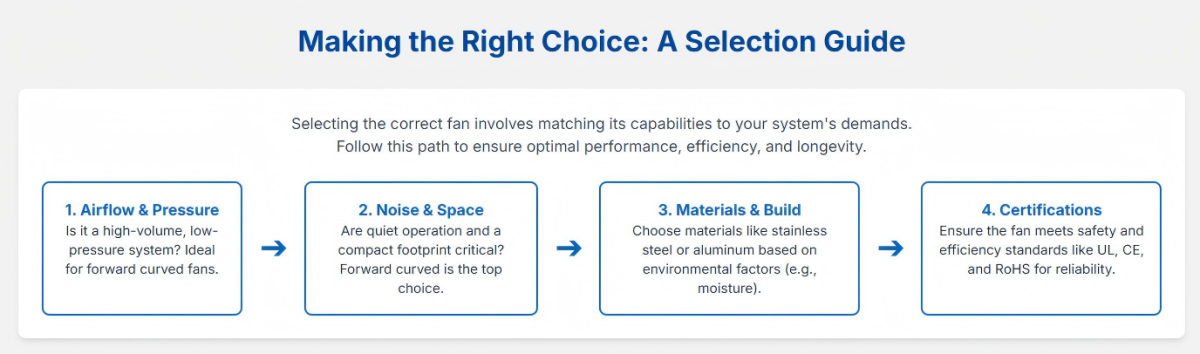

Pick the right fan size, material, and certifications. This helps match your HVAC system’s airflow, space, and safety needs. This gives you the best results.

Forward Curved Centrifugal Fans

What Are Forward Curved Centrifugal Fans

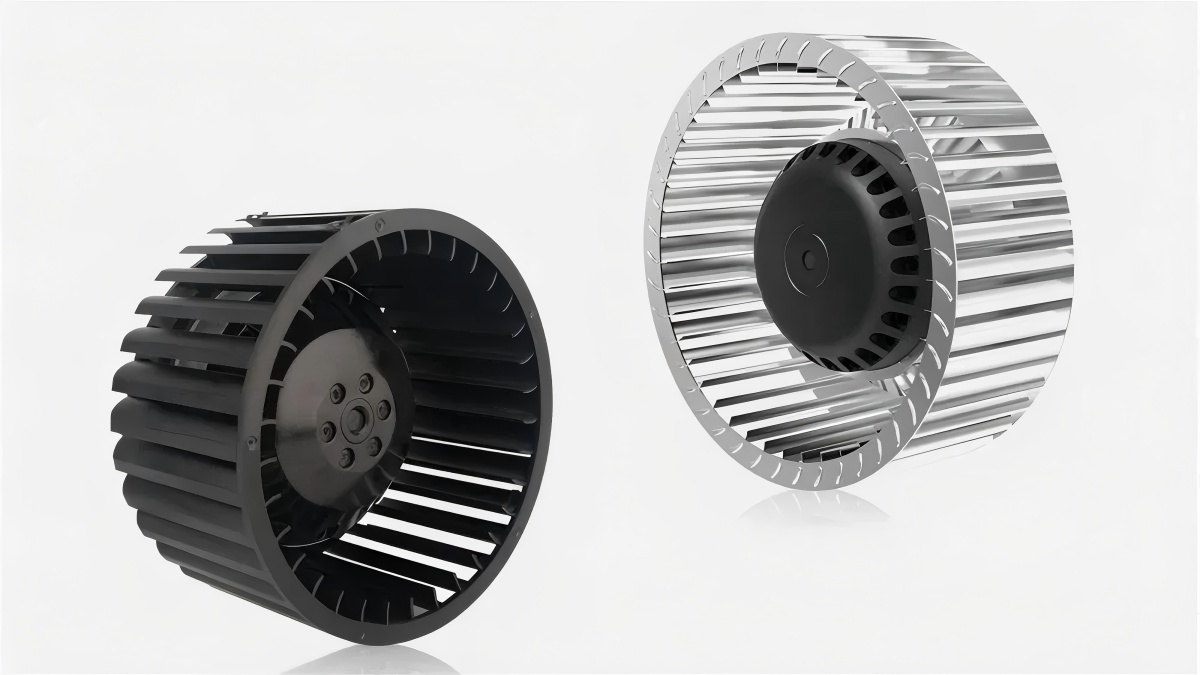

You can find forward curved centrifugal fans in many HVAC systems. These centrifugal fans have blades that curve the same way the fan spins. This shape helps move a lot of air at slow speeds. People call them "squirrel cage" fans because the impeller looks like a hamster wheel. This name shows they are small and quiet, so many industries use them.

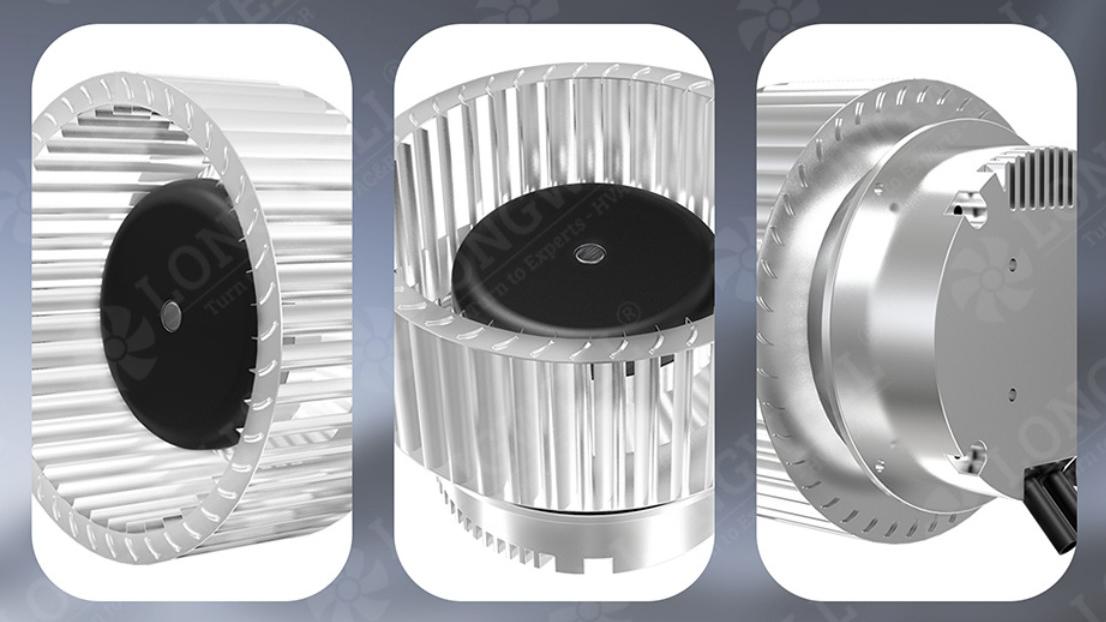

A forward centrifugal fan has a hub with many short blades. The blade tips point forward, following the spin. The impeller sits inside a casing that can be round or square. The casing often has a spiral shape to guide air and keep the airflow steady. You can use these centrifugal fans for clean or dusty air. This makes them useful in many places.

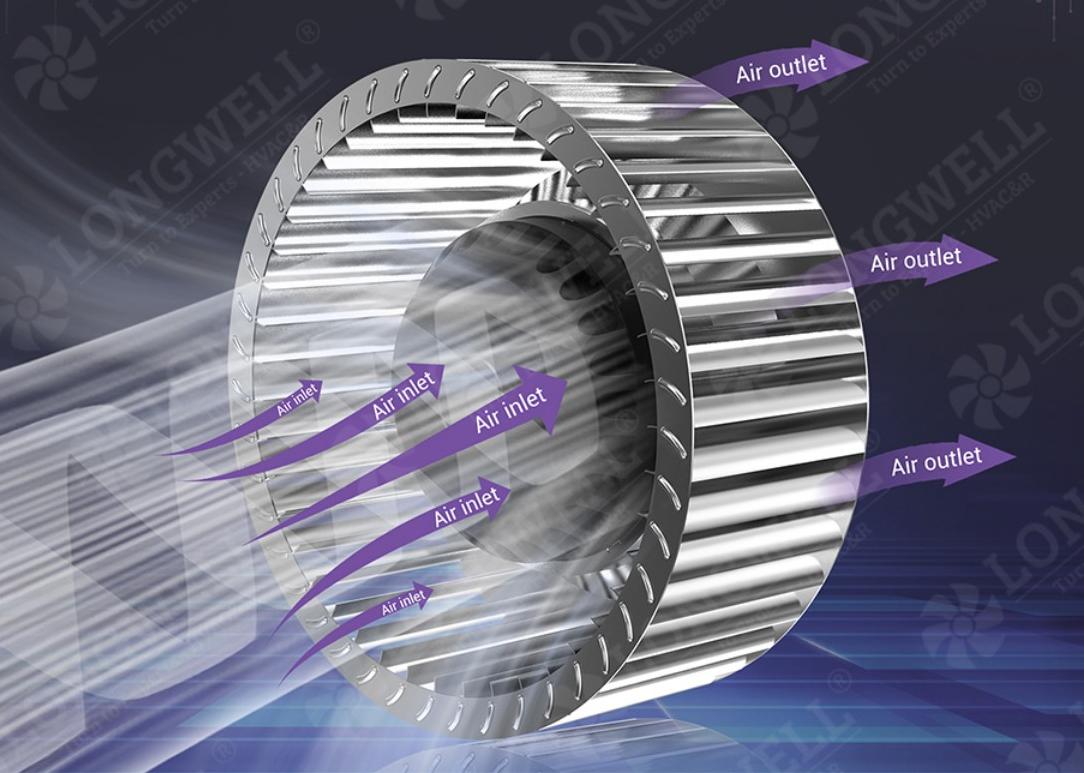

How Forward Curved Fans Work

When you turn on a forward curved centrifugal fan, the motor spins the impeller. The curved blades grab air and push it out from the center. This creates a force that moves air through the fan and into ducts. The special fan design lets the fan move lots of air at slow speeds. You get steady airflow, which is important for HVAC systems.

Other centrifugal fans, like backward curved types, work better at higher pressures. Forward curved centrifugal fans work best at lower pressures. The blade design lets you run the fan faster, but the pressure stays low. This makes these centrifugal fans good when you need lots of air but not much resistance. The fan design also helps make less noise and less turbulence, so they are quieter.

Key Features

You get many good features when you pick forward curved centrifugal fans:

Blade Design: The blades lean forward in the same direction as the spin. This fan design helps the fan work better and makes less noise.

Casing Types: The casing often has a spiral shape called a volute. This shape guides the air and keeps the airflow steady. It helps the fan work better.

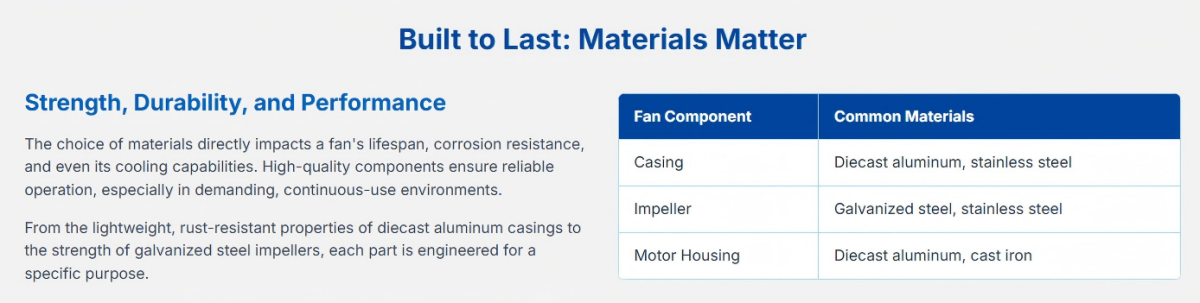

Material Choices: Makers use galvanized steel, stainless steel, and diecast aluminum for different parts of the centrifugal fan. These materials are strong, resist rust, and help cool the fan.

Here is a table that shows common materials and how they help:

Fan Component | Common Materials | Impact on Performance |

|---|---|---|

Casing | Diecast aluminum, stainless steel | Light, strong, resists rust, helps cool the fan |

Impeller | Galvanized steel, stainless steel | Strong, resists rust, made with care |

Motor Housing | Diecast aluminum, cast iron | Cools well, light, strong, good for tough places |

Compact Fan Design: The squirrel cage shape makes these centrifugal fans small and easy to fit in tight spots.

Versatility: You can use these centrifugal fans in HVAC, electronics cooling, and for moving air in general.

Performance: New fan design lets the fan reach up to 14 kPa pressure. The pressure drops a bit, but power goes up as airflow increases.

Tip: When you pick a forward centrifugal fan, match the fan design and material to your needs. This helps the fan last longer and work well.

You get a quiet, strong, and efficient fan when you use forward curved centrifugal fans in your HVAC system. Their special fan design, material choices, and small size make them a great pick for many air systems.

Explore Longwell's Forward Curved Fans

Discover energy-efficient, quiet, and reliable airflow solutions for your HVAC needs with Longwell's Forward Curved Centrifugal Fans.

Benefits in HVAC

Quiet Operation

You want your building to be quiet. Forward curved centrifugal fans help make less noise. Their special blade shape cuts down on air turbulence. This means the fan is quieter, even when it spins fast. The squirrel cage design spreads air out evenly. This also helps lower the sound. You can use these centrifugal fans in places like offices, hospitals, and schools. These places need quiet fans.

Longwell’s EC and AC series centrifugal fans have advanced motors. They also use impellers that are balanced very well. These features help stop shaking and loud sounds. You get a calm place to work or live. You do not lose airflow or performance. Many HVAC systems use these centrifugal fans to keep things quiet and comfortable.

Tip: Pick forward curved centrifugal fans if you want less noise. Their design helps you make a peaceful and productive space.

High Airflow

You need strong airflow to keep air fresh and cool. Forward curved centrifugal fans move a lot of air. In most HVAC systems, these centrifugal fans can move between 1,800 and 80,000 cubic meters per hour. That is about 1,059 to 47,059 cubic feet per minute. This means they work for small and big jobs. You can use them in small air units or huge ventilation systems.

You find these centrifugal fans in air conditioners and heaters. They are also in general ventilation systems. They work best when there is not much pressure. They move lots of air easily. The curved blades and good motors help keep airflow steady. You can trust these centrifugal fans to keep warehouses, gyms, and factories comfy and full of fresh air.

Big airflow helps large spaces.

Steady airflow makes indoor air better.

These centrifugal fans work well in homes and businesses.

Energy Efficiency

You want to save energy and spend less money. Forward curved centrifugal fans help you do this. Longwell’s EC series uses special motors that save up to 30% energy. This is better than old designs. The AC series also works well and has protection from getting too hot. This helps stop wasted energy and keeps the fan working.

These centrifugal fans have important safety and green certifications. They have CE, UL, RoHS, CCC, and ETL marks. The AC series is UL Certified and RoHS Compliant. The EC series meets CCC and RoHS rules. These show the fans are safe and good for the environment. You can trust your HVAC system to run safely and use less energy.

You get lower energy bills, less fixing, and fans that last longer. The smart design gives you more air with less power. This helps you reach energy goals in new and old HVAC systems.

Note: Certified centrifugal fans help save energy. They also help you follow building codes and green rules.

Comparison with Other Centrifugal Fans

Forward vs Backward Curved

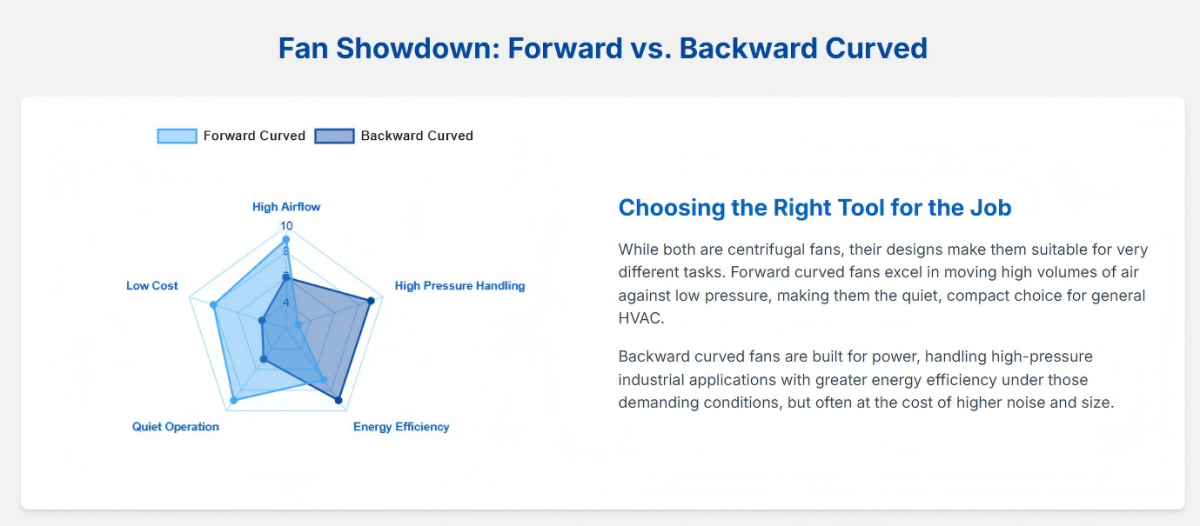

When you look at forward curved centrifugal fans and backward curved centrifugal fans, you see they work differently. Forward curved centrifugal fans have blades that bend the same way the fan spins. This shape helps move a lot of air at low or medium pressure. These centrifugal fans are quieter and cost less. Backward curved centrifugal fans have blades that bend away from the airflow. These centrifugal fans can handle more pressure and are more efficient. You often find backward curved centrifugal fans in factories where strong airflow is needed.

Here is a table to show the main differences:

Feature | Forward Curved Fans | Backward Curved Fans |

|---|---|---|

Airflow | High airflow, low static pressure | Lower airflow, high static pressure |

Energy Efficiency | More efficient in low-pressure applications | More efficient in high-pressure applications |

Noise | Quieter operation | Can be louder in certain applications |

Lifespan | Shorter lifespan, more wear and tear | Longer lifespan, more durable |

Cost | Lower initial cost | Higher initial cost |

Applications | Residential HVAC, low-pressure systems | Industrial, high-pressure HVAC systems |

Tip: Pick the centrifugal fan that fits your airflow and pressure needs. This helps your system work its best.

Efficiency Differences

You want your HVAC system to use less energy and work well. Backward curved centrifugal fans are more efficient in the same conditions. Their blade shape and bigger size help control air and save energy. They work better when you need high pressure. Forward curved centrifugal fans move a lot of air and are quieter, but they lose efficiency at high pressure. Use forward curved centrifugal fans for low-pressure jobs where you want steady and quiet air.

Backward curved centrifugal fans save more energy in hard jobs.

Forward curved centrifugal fans are best for steady, low-pressure air.

Application Fit

You need to choose the right centrifugal fan for your space. Forward curved centrifugal fans are best for HVAC systems that need lots of air at low pressure. You find these centrifugal fans in homes, offices, and small spaces. They work well for bathroom fans, kitchen vents, and cooling electronics. Their small size and lower price make them a good pick for many uses.

Backward curved centrifugal fans are better for factories, workshops, and places with dust or high resistance. You use these centrifugal fans when you need strong air and long-lasting fans. Always match the centrifugal fan to your system’s needs for the best results.

Applications in HVAC

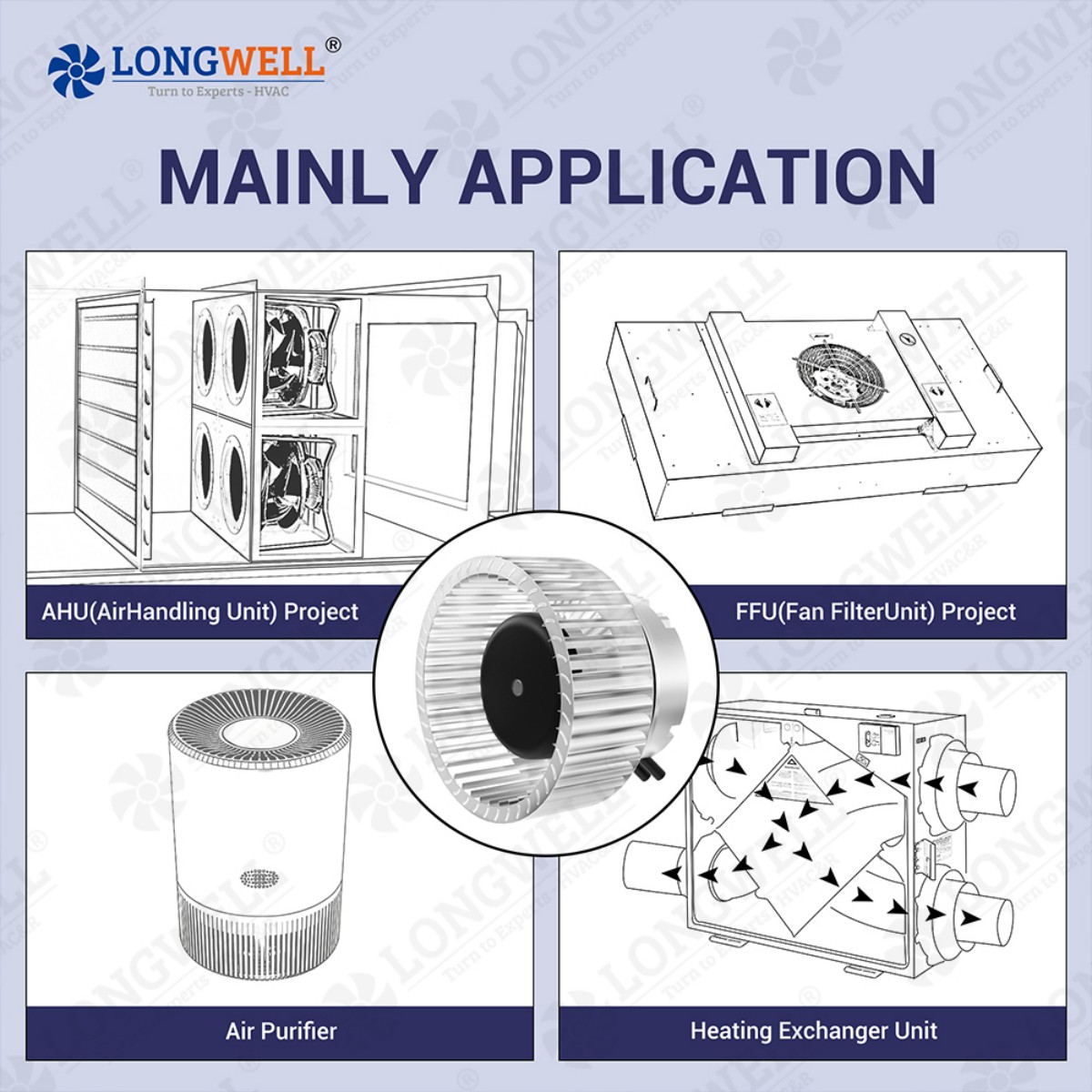

Air Handling Units

Forward curved centrifugal fans are used in air handling units. These industrial fans move a lot of air in hvac systems. The squirrel cage design lets the industrial fan fit in small spaces. You get steady airflow, so every room stays the same temperature. In commercial hvac systems, these centrifugal fans help control humidity and catch dust. They work all the time in both small and big buildings. Their quiet sound makes them great for offices, hospitals, and schools.

Electronics Cooling

It is important to keep electronics cool so they do not overheat. Forward curved centrifugal fans are good for electronics cooling. They give high airflow even at lower speeds. This industrial fan design makes less noise, which is good for quiet places like server rooms. You can trust these centrifugal fans to move air over circuit boards and power supplies. Important things to check are airflow, pressure, noise, and energy use. The industrial fan also helps control temperature by making air curtains. These air curtains keep hot and cool areas apart. This helps control heat and saves energy in your ventilation system.

General Ventilation

Forward curved centrifugal fans are used for general ventilation in many industries. These industrial fans can move a lot of air, so they are good for big places like warehouses, gyms, and factories. The industrial fan blades make less noise by cutting down on turbulence. In commercial hvac, these centrifugal fans help keep air fresh and remove old air. You save money because they are easy to take care of and cost less. When you pick a centrifugal fan, make sure it fits your airflow, pressure, and space needs. These industrial fans work in homes and businesses, and they can handle wet or dusty air.

Tip: Always match the industrial fan’s airflow and pressure to your system’s needs for the best results in all hvac systems.

When to Use Forward Centrifugal Fan

Ideal Scenarios

Pick centrifugal fans when your HVAC system needs to move lots of air. They work best when the pressure is low or medium. These industrial fan units are good for clean places like offices, schools, and homes. They run quietly, which is important where people work or sleep. Their small size lets you put them in tight spots. This makes them smart for small air handling units or electronics cooling.

Here are some times when centrifugal fans are a good choice:

You need lots of airflow but not much resistance.

Your system must be quiet, like in homes or offices.

You want an industrial fan that saves money for general ventilation.

The air is clean with little dust or dirt.

You need a strong industrial fan for air handling units that run all the time.

Tip: Use centrifugal fans in HVAC systems where steady airflow and quiet sound are important. These industrial fan choices help you save energy and keep people comfortable.

Limitations

Centrifugal fans have some limits you should know about before picking them for your industrial fan system. They do not work well if the pressure is high or the air is dirty. You must clean them often to keep them working well. The table below shows the main limits and how they change your HVAC design:

Limitation | Impact on HVAC System Design |

|---|---|

Lower efficiency at higher pressures | Not good for systems with high pressure; airflow and system efficiency go down. |

Limited static pressure capability | Only works for low pressure; not good for high resistance or big pressure drops. |

Sensitivity to dust and debris | Needs clean air; more cleaning and changes to design for easy access and good air. |

Need for regular blade cleaning | More cleaning needed, which means more downtime and higher costs. |

Do not use centrifugal fans in places with lots of dust or where you need to push air through long ducts with high resistance. These industrial fan types need regular care to keep working well. If your system has high pressure or dirty air, pick a different industrial fan.

Centrifugal Fan Selection

Airflow and Pressure

When you pick a centrifugal fan for HVAC, check how much air you need to move. Every room or building is different. You must know the airflow and how hard it is for air to move through the system. Centrifugal fans work best when the size and speed match what your system needs. If the fan is too small, not enough air will move. If the fan is too big, you might waste energy.

Look at the static pressure in your ducts. Forward curved centrifugal fans are good for low or medium pressure. You can use them in air handling units, electronics cooling, and for general ventilation. Always make sure the centrifugal fan fits your airflow needs for the best results.

Noise and Space

Noise is important in many HVAC systems. You want quiet places in offices, schools, and hospitals. Forward curved centrifugal fans help keep noise down because of their special blade shape. The squirrel cage design spreads air out and keeps things quiet. When you put in a centrifugal fan, check how much space you have. These fans are small and fit in tight spots.

If you need something quiet and small, forward curved centrifugal fans are a good pick. You can use them where people work or sleep. Always measure your space before choosing a fan.

Certifications and Safety

Safety and quality matter in commercial HVAC systems. You should pick centrifugal fans that have top certifications. Longwell’s centrifugal fans meet international safety and performance rules. Both the LWFE Series EC and LWFA Series AC forward curved centrifugal fans have certifications like CE, UL, RoHS, CCC, and ETL. These fans also meet the UL507 safety rule and have ETL certification from Intertek.

Here is a table that shows key features:

Feature Category | LWFE Series EC Forward Curved Fan | LWFA Series AC Forward Curved Fan |

|---|---|---|

Motor Type | Brushless EC external rotor motor | AC External Rotor Motor |

Certification | CE, UL, RoHS, CCC, ETL | CE, UL, RoHS, CCC, ETL |

Material | Galvanised sheet steel | Galvanised sheet steel |

Mode of operation: | S1 | S1 |

Protection Rating | IP55/IP54 | IP54 |

Operating Temperature | -30°C to +60°C | -30°C to +60°C |

Bearing Type | Maintenance-free ball bearings | Maintenance-free ball bearings |

Insulation Class | Class “B” insulation | Class “B”,"F" insulation |

Operational Mode | Continuous operation (S1) | Continuous operation (S1) |

You can trust these centrifugal fans to be safe and last a long time. Always check for certifications before you buy a centrifugal fan for your HVAC system.

Tip: Pick a centrifugal fan that matches your airflow, space, and safety needs. This helps your HVAC system work better and last longer.

Installation and Maintenance

Best Practices

You want your centrifugal fans to work well for years. First, check how much air and pressure your system needs. Pick the right centrifugal fan for your job. Get the spot ready by lining up the fan and ducts. Make sure the fan is tight and there is space for air. Always follow the maker’s steps for wiring and safety. After you put in the fan, test how it works and fix things if needed. Check the centrifugal fan often to find problems early and keep it running well.

Installation Checklist:

Check how much air and pressure you need.

Pick the right centrifugal fan for your system.

Line up the fan and ducts for smooth air.

Follow all steps from the maker.

Test the centrifugal fan after you put it in.

Plan to check the centrifugal fan often.

Tip: Lining up and tightening the centrifugal fan helps stop shaking and noise.

Maintenance Tips

Taking care of centrifugal fans helps them work better. Clean the blades and bearings often so dust does not build up. Check the filters and change them when they get dirty. Oil the bearings every few months. Look at the belts to see if they are tight and straight. Check the motor and wires at least once a year. Balance the blades and check the controls every year.

Maintenance Task | Frequency | Benefit |

|---|---|---|

Visual Inspections | Monthly | Find damage and dirt |

Lubricate Bearings | 3-6 months | Stop parts from wearing out |

Check Belt Tension | 3-6 months | Stop slipping and damage |

Motor Maintenance | 6-12 months | Keep the motor from breaking |

Full System Check | 6-12 months | Make sure it is safe and works best |

Note: Clean filters and balanced blades help centrifugal fans use less power.

Troubleshooting

Sometimes centrifugal fans have problems like less air, loud sounds, or shaking. If air is low, look for dirty filters or blocked ducts. Clean the impeller and filters to help the air move again. Loud sounds can mean loose bolts or parts that are not lined up. Tighten bolts and line up the centrifugal fan. Shaking can come from blades that are not balanced or old bearings. Balance the blades and change broken parts. If the motor gets too hot, look for dust, blocked vents, or too much load. Change the fan speed with a special drive if you need to.

Check and clear anything blocking the ducts.

Clean the impeller and filters often.

Make sure all parts are tight and lined up.

Change old bearings and broken blades.

Watch the motor heat and how much air moves.

Call an expert if the problem does not go away or if you hear strange sounds from your centrifugal fans.

Challenges and Solutions

Noise Issues

Sometimes, centrifugal fans make noise in your HVAC system. This noise often happens when the impeller and cut-off area touch. Other things like shaking, loose parts, or air hitting the fan case can also make noise. If you use an industrial fan in a quiet room, the noise can bother people.

You can try these ways to make the fan quieter:

Put silencers at the fan’s inlet and outlet.

Cover the fan housing with noise-proof panels or coatings.

Seal any open spaces around the fan shaft.

Use vibration isolators to stop shaking from spreading.

Mount the industrial fan tightly on a flat surface.

Pick the right size centrifugal fan so you do not get too much airflow.

Look for and take out anything stuck inside the industrial fan.

You can also change the impeller blade shape or use special materials on the cut-off area to help lower noise even more.

Pressure Drops

Centrifugal fans work best with low or medium pressure. If your HVAC system has high resistance, airflow can drop. This is because centrifugal fans cannot handle high static pressure. When you use an industrial fan in a high-pressure system, it may not move enough air.

To fix this, always match the industrial fan to your system’s pressure needs. If you need higher pressure, pick a different type of industrial fan. Always check airflow and noise before choosing centrifugal fans for your HVAC system.

Compatibility

When you add centrifugal fans to an old HVAC system, you might have problems. The table below shows common issues and what they mean for your industrial fan setup:

Compatibility Challenge | Explanation |

|---|---|

Lower Efficiency at Higher Pressures | Centrifugal fans use more energy in high-pressure systems. |

Limited High-Pressure Capability | Not suitable for HVAC systems with high resistance. |

Susceptibility to Dust and Debris | Dust can build up on the industrial fan blades and lower performance. |

Performance Degradation | Centrifugal fans may not work well outside their best conditions. |

Higher RPM Operation | Fans may run faster, causing more noise and energy use. |

Suitability for Low-Pressure Systems | Best for low-pressure, not high-pressure, HVAC systems. |

You should always check what your system needs before you put in a new industrial fan. This helps you get the best results from your centrifugal fans.

Trends in Centrifugal Fans

New Technologies

New technologies are changing how centrifugal fans work today. Makers now add smart sensors to these fans. The sensors check fan speed, temperature, and vibration. They help you find problems early and keep things working well. Some centrifugal fans can connect to building automation systems. This lets you control airflow and check how the fan works from your phone or computer.

Many new centrifugal fans use brushless EC motors. These motors last longer and use less energy. You can change the fan speed to fit what you need. This helps save power and makes less noise. Some fans use light materials like special plastics or aluminum. These materials make the fans easy to put in and move.

Note: Smart controls and new motors help you get more from your centrifugal fans with less work.

Efficiency Improvements

You want your HVAC system to use less energy and last longer. New centrifugal fans give better airflow and make less noise. The new blade shapes lower turbulence. This means you get steady air and a quieter fan.

Makers now design centrifugal fans to work well at many speeds. You can set the fan to run slower if you need less air. This saves energy and lowers your bills. Many new fans meet strict safety and quality rules. You can trust these fans to work even in tough places.

Here is a quick table showing recent improvements:

Feature | Benefit |

|---|---|

EC Motors | Lower power use |

Smart Sensors | Early problem detection |

Better Blade Design | Less noise, more airflow |

Lightweight Materials | Easier installation |

Tip: Pick centrifugal fans with the newest features to help your system work better and last longer.

You get lots of good things when you pick forward curved centrifugal fans for your HVAC system. These fans are best for quiet places and jobs with low pressure. They also help you save money. The table below shows the main ways these fans are different:

Aspect | Forward Curved Fans | Backward Curved Fans |

|---|---|---|

Efficiency | Lower | Higher |

Pressure Handling | Low static pressure | High static pressure |

Noise Level | Quieter | Noisier |

Always check how big your space is. Make sure the fan’s material fits where you use it. Look at how much air you need to move. Pick fans that are certified and save energy. Try to use new technology to get the best results.

FAQ

What is the main advantage of using a forward curved centrifugal fan in HVAC systems?

These fans move a lot of air and stay quiet. The special blade shape helps push air well. This makes them good for places where you want less noise and steady air.

How often should you perform maintenance on these fans?

Check and clean your fan every three to six months. Doing this stops dust from building up. It also keeps the fan working well and lasting longer. Always follow the maker’s plan for taking care of the fan.

Can you use forward curved centrifugal fans in dusty environments?

You can use these fans where there is a little dust. Do not use them where there is a lot of dust. Too much dust can stick to the blades and slow the fan down. Use good filters and clean the fan often to keep air moving well.

Are Longwell’s forward curved centrifugal fans energy efficient?

Yes, these fans use new motors and smart blade shapes. You can save up to 30% energy compared to old fans. They also have top safety and energy certificates.

See Also

The Importance Of Centrifugal Fans In HVAC And Industry

Selecting The Best Centrifugal Fan For Your 2025 Needs

A Complete Guide To Cross Flow Fan Energy Efficiency Today