How to Choose the Right Axial Fan for Your Application in 2025

To pick the right axial fan, first know your airflow and static pressure needs. Small systems might need up to 5,000 CFM. Big systems often need more than 20,000 CFM. Match the fan’s static pressure to your system’s resistance. This helps you save energy and avoid bad performance. Use trusted standards like ANSI/AMCA for correct measurements. Think about efficiency, noise, durability, compliance, and cost. Take it step by step to feel sure you picked the right axial fan.

Key Takeaways

Find out how much airflow and pressure you need before picking an axial fan. This helps the fan work well and saves energy. - Choose the right fan type and size for your job and system. This gives you better efficiency and less noise. - Select fans made with strong materials and good safety features. This makes them last longer and keeps your system safe. - Clean and oil your fan often. This helps it work better and last longer. - Think about all costs, like energy and repairs, not just the first price. This can help you save money over time.

Application Needs

Identify Your Application

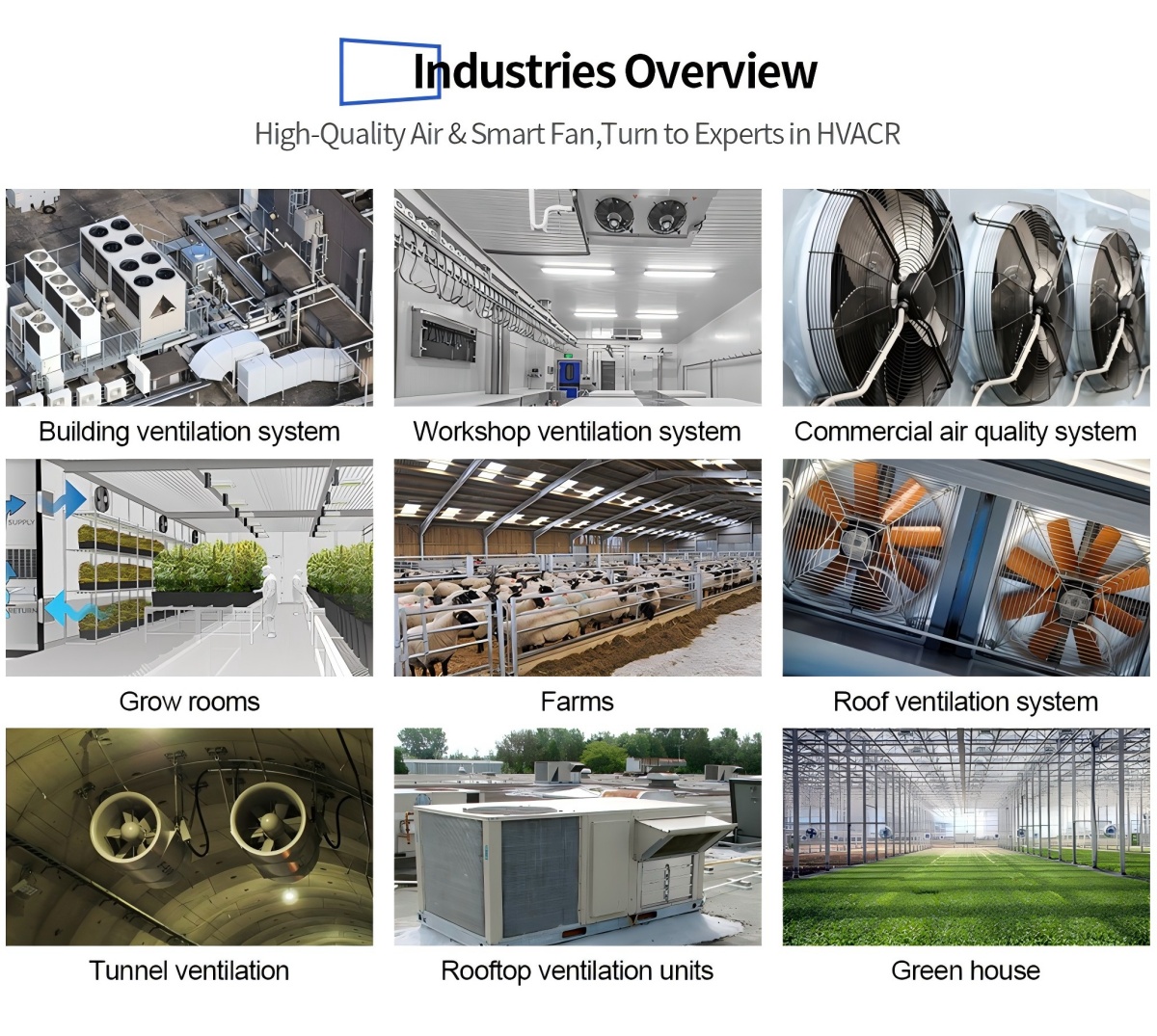

First, figure out where you will use the axial fan. Every place has its own needs. HVAC systems need fans that move a lot of air quietly. This keeps rooms comfortable for people. Electronics cooling needs fans that fit in small spaces. These fans must cool sensitive equipment. Factories and warehouses need strong fans. These fans must handle dust, heat, or chemicals.

Tip: Pick a fan that matches your needs. This helps you get the right airflow, noise, and energy use. Axial fan applications are used in many places. Some examples are data centers, paint booths, and farm buildings. Always think about how much cooling and heat transfer you need.

Here is a table that shows how different industrial fan models fit certain needs:

Fan Model | Key Specifications | Application Example | Significance |

|---|---|---|---|

12-inch Upyouths | Large airflow, low noise, durable blades | Industrial ventilation | Quiet, energy efficient, long-lasting |

10-inch Compact | Adjustable airflow, compact size | Small warehouses, tight spaces | Flexible, portable, energy saving |

Model A | Strong airflow, explosion-proof motor | Paint booths, chemical plants | Safe, steady airflow, handles hazardous areas |

Model B | Lightweight, stainless steel, portable | Production areas, flexible needs | Easy to move, energy efficient, safe |

Define System Requirements

Once you know your application, list your system needs. Write down how much cooling you need. Think about how much air must move. Also, think about the pressure in your system. A fan in a long duct needs to push against more resistance. A fan in open space just needs to move air.

Measure airflow (CFM), static pressure, and temperature.

Check the size and mounting options for your space.

Look at motor efficiency and power use to keep costs low.

Make sure the fan meets noise limits for your environment.

Choose materials that last in your conditions, like high humidity or chemicals.

You can use software tools to help you pick the best fan. These tools show you fan curves, noise, and performance. Always check if your axial fan meets all your needs for safety and rules. This step helps you avoid problems. It also makes sure your industrial fan works well for a long time.

Airflow & Pressure

To pick the right axial fan, you need to know your airflow and pressure needs. You should find out how much air you want to move. You also need to know how hard it is for air to move in your system. This helps you avoid problems like loud noise or wasted energy. It also helps you get good cooling.

Calculate Airflow (CFM)

You must figure out how much airflow your application needs. Airflow is measured in cubic feet per minute (CFM). This number tells you how much air the fan moves each minute. To guess the right CFM, think about how much heat your system makes. Also, think about how much temperature rise you can allow.

Tip: Use this formula:

Q = 40W / (T2 - T1)

Q is air volume (CFM), W is heat made (watts), T1 is intake temperature, and T2 is exhaust temperature.

Engineers use AMCA Standard 210 double chamber tools to measure airflow. This method finds the most airflow by changing nozzle settings. You can trust these numbers because they follow strict rules. These rules make sure your airflow and pressure numbers are correct.

Determine Static Pressure

Static pressure is the force the fan needs to push air through your system. You measure static pressure in Pascals (Pa) or inches of water (inH2O). You need this number to match your fan to your system.

To measure static pressure, use a wind tunnel built to ANSI/AMCA 210-16 rules. This setup uses an orifice plate to check airflow rates. It also uses a honeycomb flow straightener to keep air moving one way. A throttling device lets you control backpressure. These tools help you get exact numbers for your needs.

The double chamber method checks the pressure difference between two chambers.

This method follows AMCA standard 210, which is used everywhere.

It gives you fast and correct airflow and static pressure numbers.

An extra blower can help you check different points on the static pressure curve.

Computer links make data collection easy and correct.

Knowing static pressure helps you pick a fan that can handle your system’s resistance. This step is important for systems that need lots of airflow or have long ducts.

Match Fan Curves

After you know your airflow and static pressure, you need to match your fan to your system. Every fan has a performance curve. This curve shows how much air the fan moves at different pressures. Your system also has a curve called the system characteristic curve. This curve shows how resistance changes as airflow goes up.

The fan and system curves meet at one spot. This is your system operating point. At this point, the fan gives your system the airflow it needs at the right pressure. If you pick a fan that works near its best efficiency at this point, you save energy and get better cooling.

Technical reports show that putting system resistance curves on fan performance curves helps you find the best match. The fan should work near its highest efficiency, which is often at about one-third of its top pressure. If you only look at free air performance, you might miss big energy savings. Matching the fan curve to your system point leads to better design and lower costs.

Note: The fan always runs where the fan curve and system curve cross. This is where you get the best mix of high airflow and efficiency.

Case studies show that picking fans near their best efficiency improves cooling and saves energy. You should always check both curves before you choose. This step makes sure your axial fan meets your airflow and pressure needs and gives your application the high airflow it needs.

Selecting Fans & Sizing

Axial Fan Types

There are three main types of axial fans. Each type is good for different jobs. The table below helps you see the differences:

Fan Type | Pressure Capability | Typical Application | Efficiency Aspect |

|---|---|---|---|

Propeller | Low pressure | High-volume, low-resistance airflow | Simple design, less efficient at higher pressures |

Tube Axial | Moderate pressure | General ventilation | Venturi shape improves flow and reduces vortices |

Vane Axial | High pressure | High-pressure applications | Guide vanes boost efficiency and pressure performance |

Propeller fans move lots of air but only if there is little resistance. Tube axial fans can handle more pressure and are good for most ventilation jobs. Vane axial fans are best for tough jobs that need high pressure and strong airflow. Always pick the fan type that matches your job for the best results.

Select the Right Fan Size

To pick a fan, first know your airflow and pressure needs. Check the cubic feet per minute (CFM) and static pressure. These numbers tell you how much air you need and how hard the fan must work. You should also look at the Fan Energy Index (FEI). A higher FEI means the fan saves more energy.

Do not pick a fan that is too big. Big fans waste energy and make more noise. Try to choose a fan that works close to its best efficiency point. This helps your industrial fan last longer and saves money. Always use data that is corrected to standard air conditions. This makes it easier to compare different fans.

Tip: Use design tools to enter your system’s flow rate, pressure, and air density. These tools help you try out different fan sizes and types. They also show you curves for airflow, pressure, power, and noise.

Mounting Options

How you mount your industrial fan is very important. You need to match the mounting type to your system. The AMCA Installation Types (A, B, C, D) show different ways to set up ducting. Each type changes how the fan works.

Pick a mounting option that fits your space and airflow path.

Do not use sharp duct turns or bad inlet or outlet setups.

Good mounting helps your fan run smoothly and last longer.

Always think about fan size and mounting together. This helps you get the best performance and longest life from your axial fan.

Efficiency & Noise

Energy Efficiency

You want your axial fan to use less energy but still move enough air. New fans have better motors and special blades. These help the fan run slower and save up to 85% more electricity than old fans. If you pick a fan with high energy efficiency, it will also be quieter. This matters in places like data centers and electronics cooling. In these places, saving energy and keeping noise low are both important. New things like EC motors and smart speed controls help you get the best results. These upgrades let you use more equipment without making more noise or raising your energy bill.

Tip: Pick fans with high energy efficiency ratings. These fans usually have labels or certificates that show how well they work.

Noise Level

You need to check how loud a fan is before you buy it. Fans make noise from moving air and from the motor. Engineers test fans in special rooms to measure sound. They use microphones and sound meters to check noise at different speeds and pressures. They listen for the steady hum and extra sounds from the blades. Tests also check noise with and without things blocking the airflow. This helps you know how loud the fan will be in your real setup.

Sound pressure is measured in decibels (dBA).

Tests follow AMCA rules so you can compare fans.

Noise can change if you add ducts or other parts near the fan.

If you want a quiet place, pick a fan with low noise ratings. This is important for offices, schools, and hospitals.

Power Consumption

You should always check motor efficiency and power use when you look at fans. The power a fan uses depends on how much air it moves and how much pressure it works against. Some fans, like ones with more blades, use more power and make more heat. Others, with fewer blades, use less power and stay cooler. Engineers use math and tests to compare different fan designs. They check how much power goes into the fan and how much is used to move air. This helps you find a fan that saves energy and keeps costs low.

Fan Design | Number of Blades | Power Use | Heat Output |

|---|---|---|---|

2-bladed | 2 | Low | Low |

12-bladed | 12 | High | High |

Picking the right fan helps you balance airflow, energy efficiency, and noise for your needs.

Materials & Durability

Fan Materials

Picking the right materials helps your axial fan last longer. Many fans are made from steel, aluminum, or composite materials. Composite materials help stop the blades from bending or breaking. Steel is strong and can hold heavy loads, but it can get tired if not made well. Some fans have special coatings to stop rust and wear. Motors with insulation class F can work in hot places up to 155°C. Fans with IP54, IP55, IP65, or IP66 ratings keep out dust and water. This helps them work well in tough places.

Overspeed tests check if the fan can spin faster than normal and not break.

After these tests, experts look for cracks or damage in the welded joints and hub.

Temperature rise tests make sure the motor does not get too hot after running for a long time.

Environmental Suitability

You need to pick a fan that fits where you will use it. If your area has lots of humidity, dust, or chemicals, choose fans with coatings or corrosion-resistant materials. Stainless steel fans go through tests to show they can handle wet or harsh places. For example, small punch tests on stainless steel show if the metal cracks in hot, high-pressure water. This means you can trust these fans in chemical plants or outside.

Tip: Always check the fan’s rating for dust and water resistance. This helps you avoid problems in tough environmental conditions.

Maintenance Needs

Taking care of your fan helps it last longer and work better. Clean the blades and housing often so dust does not build up. Lubricate the bearings and motor as the maker says. Check belts and bolts every month to keep them tight and balanced. Change worn parts right away to stop bigger problems.

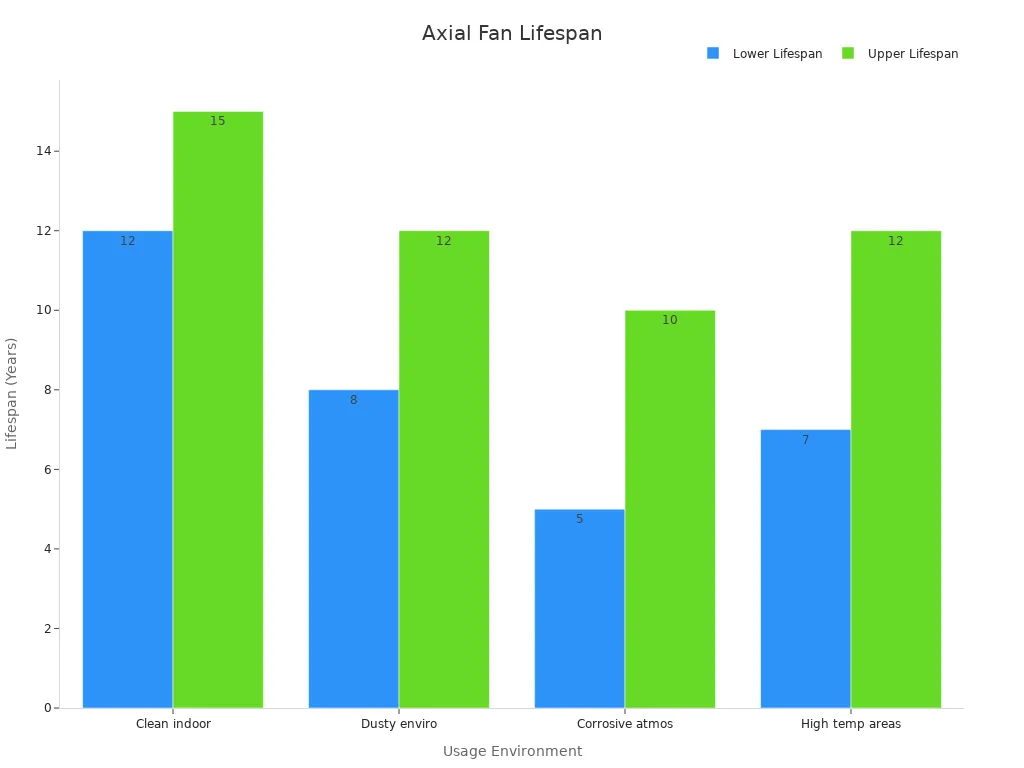

Usage Environment | Expected Lifespan (Years) | Key Maintenance Practices |

|---|---|---|

Clean, indoor settings | 12-15+ | Regular cleaning, bearing lubrication |

Dusty environments | 8-12 | Frequent cleaning, filter changes |

Corrosive atmospheres | 5-10 | Corrosion-resistant treatments, frequent inspections |

High-temperature areas | 7-12 | Heat-resistant components, specialized lubricants |

Lubricating bearings can help them last up to 40% longer.

Using a variable frequency drive (VFD) can add up to 25% more life by lowering stress.

Good installation and alignment are important for the best material and durability.

Compliance & Safety

Certifications

You need to check if your axial fan has the right certifications. These certifications mean the fan is safe and works well. Many groups test fans to make sure they follow the rules. Look at the table below for some important standards:

Compliance Standard / Certification | Description / Purpose |

|---|---|

ANSI/AMCA 210-16 | Tests fan airflow and pressure in labs. |

ANSI/AMCA 230-23 | Rates air circulating fans for performance. |

ANSI/AMCA 300-14 | Measures fan sound in special rooms. |

ISO 5801:2017 | Tests fan performance using airways. |

ISO 13347 series | Checks fan sound power levels. |

AMCA Certified Ratings Program | Guides rating and certification, uses AMCA seal. |

EU Regulation (EU) No 327/2011 | Verifies fan efficiency for EU rules. |

UL (Underwriters Laboratories) | Certifies electrical safety and design. |

CE (European Conformity) | Meets European safety and health standards. |

RCM (Regulatory Compliance Mark) | Follows electrical safety in Australia and New Zealand. |

You should look for these marks on your fan:

ENERGY STAR® shows the fan saves energy.

UL means the fan is safe with electricity.

CE means it meets European safety rules.

HVI checks airflow and noise.

RCM is for Australia and New Zealand.

Many companies use ISO 5801:2017 to test their fans. They also keep a quality system with ISO 9001:2015. Some fans have ATEX and IECEx certifications. These show the fan is safe where there might be explosive gases or dust. Companies do regular checks and tests to keep these certifications.

Safety Features

You want your fan to be safe all the time. New axial fans use special designs to lower risks. Engineers use computers and real tests to check the blades and motors. They look at noise, pressure, and airflow. These tests help fans work better and stay safe.

Multi-element airfoil blades let fans run slower and make less noise.

Changing blade thickness and tip clearance can save energy and help the fan work better.

Tests show that small changes in tip clearance can make fans up to 7% more efficient.

Fans with special blade shapes move air smoothly and are less likely to break.

Tip: Always pick fans with safety features like guards, thermal protection, and emergency shut-off. These features keep you and your equipment safe.

You can trust fans that pass these tests and have these safety features. They help your system run safely every day and give you peace of mind.

Cost & Ownership

Initial Cost

When you pick an axial fan, you first see the price. Fans with smart controls and high efficiency usually cost more. Basic fans are cheaper, but advanced ones save more energy. The table below shows some things about cost and market trends:

Cost-Benefit Aspect | Description |

|---|---|

High Initial Investment | Energy-efficient fans with smart tech need more money upfront. |

Market Adoption Constraints | Small businesses may wait to buy due to high prices. |

Competition from Alternatives | Cheaper centrifugal fans can affect your decision. |

Market Segmentation | About 20% of companies still use older, less expensive fans. |

Raw Material Price Fluctuations | Steel and aluminum prices can change, raising costs. |

You also need to think about setup and installation. Some fans need special mounts or wiring, which can cost more. If you choose a fan that lasts longer, you might pay more at first. But you get better value over time.

Total Cost of Ownership

The total cost of ownership is more than just the price today. It includes energy use, repairs, and how long the fan lasts. You save money if your fan uses less power and needs fewer repairs. Here are some important things to remember:

Durable fans last longer and need fewer replacements.

Fewer moving parts mean less downtime and fewer repairs.

Long maintenance intervals help you avoid frequent service costs.

In places like data centers, efficient fans can cut cooling energy use by up to half.

Fans like the NOVENCO ZerAx® can last over 20 years and reach up to 92% efficiency. This means you spend less on energy and repairs. When you look at cost-effectiveness, paying more at first can save you money later. Picking the right fan helps your system run well and saves you money in the long run.

Choosing the Right Axial Fan: Checklist

Step-by-Step Guide

You can make picking a fan easier by using a simple checklist. This helps you remember every step and keeps your fan working well for a long time.

Identify your application

Decide if you need the fan for general air movement or for a duct system. This choice affects all the other steps.Define performance needs

Write down how much air and pressure you need. Think about how loud the fan is, how much energy it uses, and how easy it is to take care of.Choose mounting and location

Pick the best place for your fan, like on the roof, wall, or ground. Make sure there is enough room to put it in and fix it later.Select the right fan type and size

Use a fan selector tool to look at different models. Match the fan’s curve to your system for the best results.Check materials and safety features

Look for fans with strong cases, sealed ducts, and safety guards. These things help your fan last longer and keep everyone safe.Plan for installation and maintenance

Make a list for putting in your fan. Fasten the case, put in the impeller right, and seal all the parts. Plan to check and clean your fan often so it keeps working well.

Tip: Check for leaks or loose parts every month. Write down any shaking once a year to stop big problems before they start.

Common Mistakes

Many people make mistakes when picking a fan. You can avoid these problems:

Not thinking about system pressure and airflow, which makes the fan work badly.

Forgetting to make sure the ducts are tight and the fan is mounted well.

Not doing regular checks, which makes the fan break sooner and cost more.

Picking a fan just because it is cheap, not because it saves money over time.

Not using a fan selector tool, which can lead to picking the wrong size or type.

Mistake | Impact |

|---|---|

Wrong fan size | Low efficiency, high noise |

Poor installation | Vibration, leaks, breakdowns |

No maintenance plan | Shorter lifespan, more repairs |

If you pick your fan carefully and take care of it, your axial fan will work better and last longer.

You can make the right axial fan selection by following each step in this guide. Use the checklist to help you with your next project. If you face a complex system, talk to an expert for advice. Save or share this guide so you always have the best tips for your application. 🛠️

FAQ

What is the difference between an axial fan and a centrifugal fan?

Axial fans move air in a straight line. Centrifugal fans push air out at an angle. You should use axial fans for high airflow and low pressure. Centrifugal fans work better for high pressure and lower airflow.

How do I know if my fan is energy efficient?

Check for labels like ENERGY STAR® or a high Fan Energy Index (FEI). You can also look at the motor’s efficiency rating. Efficient fans use less power and save you money over time.

Can I use an axial fan outdoors?

Yes, you can use axial fans outdoors. Pick a fan with a weatherproof rating like IP55 or higher. Stainless steel or coated fans last longer outside. Always check the fan’s environmental rating before installing.

How often should I maintain my axial fan?

You should inspect and clean your fan every month. Lubricate bearings as the manufacturer suggests. Replace worn parts right away. Regular maintenance helps your fan last longer and work better.

What should I do if my fan is too noisy?

Check for loose parts or dirt on the blades. Make sure the fan is mounted correctly. You can use sound-absorbing materials or choose a fan with a lower noise rating. If noise continues, consult a professional.

See Also

Selecting The Best Centrifugal Fan For Your Needs 2025

Guide To Picking The Ideal Cross Flow Fan For Use

Key Industrial Blower Fan Innovations Manufacturers Must Follow

Understanding Blower Fans And Their Operational Principles Explained