How to Choose the Best Industrial Axial Fan

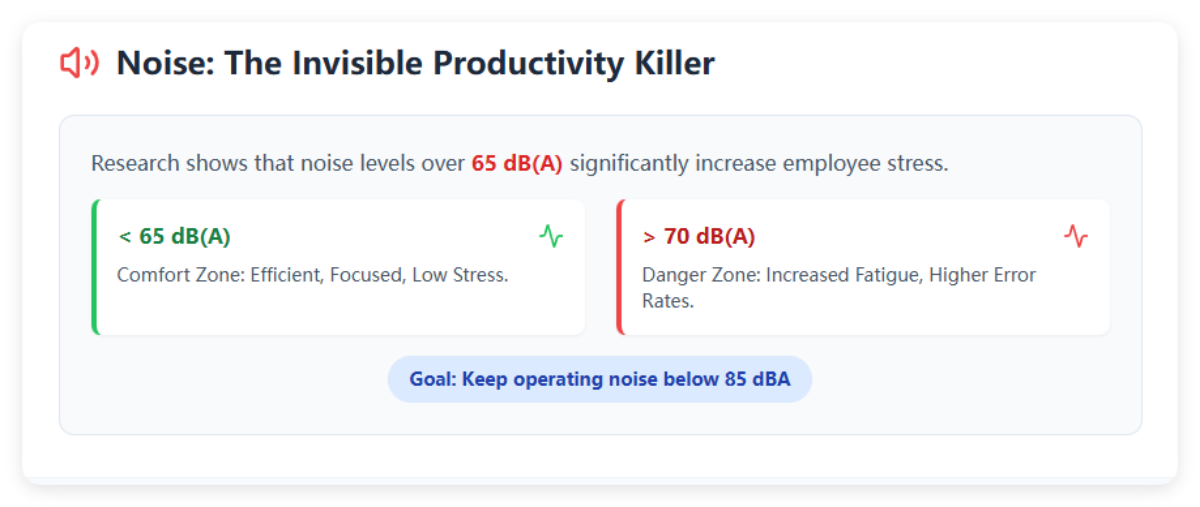

Choosing the right fan means you need to match its details to your job. Efficiency, reliability, and noise levels are important in every factory. Loud noise can make people feel stressed and tired. It can also hurt how well people work. Noise above 65 dB(A) can make stress and mental work go up. This can change how people do their jobs.

Look at the table below for more facts:

Study | Findings |

|---|---|

Golmohammadi et al. (2022) | Stress happens when noise is over 65 dB(A). |

Kang et al. (2022) | Good sound quality helps people work much better. |

Ke et al. (2021) | Machine noise makes people work harder and make more mistakes. |

Astuiti et al. (2024) | Loud noise at 70 dB makes people work harder and feel tired. |

Longwell has many choices you can trust. If you use an industrial axial fan selection guide, you can pick the best fan for your building.

Key Takeaways

Pick a fan that fits your airflow and pressure needs. This helps air move well and keeps your workspace safe.

Think about how loud the fan is when you choose one. Keeping noise under 85 dBA helps people stay healthy and work better.

Choose the best materials for your fan. Stainless steel and fiberglass do not rust or break easily. They work well in hard places.

Use a checklist to help you pick a fan. This helps you remember things like airflow, noise, and how to install it.

Take care of your fan often. Check and clean your fan every month. This helps it work well and last longer.

Industrial Axial Fan Selection Guide

What Are Industrial Axial Fans

Industrial axial fans move lots of air with little resistance. The blades spin around a center point. Air moves in the same way as the axis. This design lets you move air fast. You see these fans in factories and cooling systems. They also work in big open spaces. The industrial axial fan selection guide explains why this fan is good for many jobs. Picking the wrong fan means less airflow or wasted energy.

Key Features & Benefits

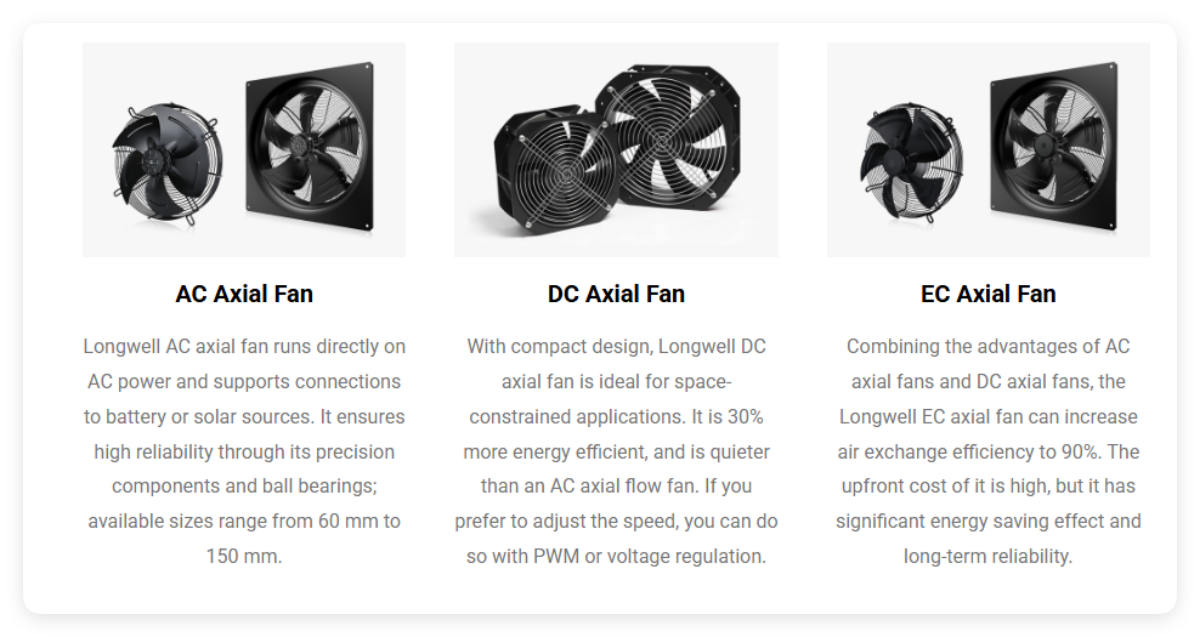

Longwell has many axial fans for hard jobs. You can choose AC, DC, or EC models. Each one works for different needs. The fans use strong materials like stainless steel, fiberglass, and plastic. These materials help the fans last longer and stop rust. You can get ducted, wall-mounted, or portable fans. The industrial axial fan selection guide shows how these features help in different places.

The right fan gives better air, fewer machine problems, and cleaner products. The table below lists some main benefits:

Benefit | Description |

|---|---|

Healthier workers | Better air helps workers stay healthy. |

Reliable fans mean less downtime. | |

Cleaner products | Cleaner air keeps products clean. |

Common Applications

Industrial axial fans are used in many places. The industrial axial fan selection guide lists common uses like HVAC, ventilation, and cooling electronics. You also find them in farms, power plants, and sports arenas. These fans help with tunnels, refrigeration, and wind tunnels. Longwell’s fans are great for these jobs because they move lots of air and are quiet. To avoid mistakes, match the fan to your job. The industrial axial fan selection guide helps you check airflow, pressure, and space for each use.

Identify Application Needs

Airflow & Pressure Requirements

You must know how much air needs to move. This is called airflow. Good airflow keeps your workspace safe. You should check the fan’s airflow capacity. This shows how much air the fan moves each minute. If the fan moves too little air, ventilation will not work. You also need to think about the pressure the fan makes. Pressure helps push air through ducts or filters. Look at the table below for what to check:

Factor | Description |

|---|---|

Airflow Requirements (CFM) | How much air the fan must move. |

Pressure Needs | How much pressure the fan must make. |

Noise Levels | How loud the fan can be for your job. |

Power Supply Compatibility | Make sure the fan works with your power. |

Application Environment | The place where the fan will be used. |

When you match airflow and pressure, you get better ventilation. This also makes your workspace safer.

Environmental & Space Considerations

You should think about where you will use the fan. High humidity can make steel blades rust. Rust makes the fan weaker and lowers airflow. Humidity can also make aluminum blades break. Moisture can change the blade’s weight. This can make the fan shake. Mold and bacteria can grow on blades in wet places. This can hurt air quality and airflow. Pick a fan that fits your space and can handle these problems.

Humidity can make steel blades rust and get weak.

Humidity can make aluminum blades break.

Moisture can cause the fan to shake.

Mold and bacteria can grow in wet places.

Mounting & Installation Options

You need to think about how to put in the fan. Some fans go on walls. Some fit in ducts. Some stand alone. The right mounting helps airflow and ventilation. Check your space before you install the fan. Make sure the fan’s airflow matches your room size. Good installation gives strong ventilation and keeps your system working well.

Axial Fan Sizes & Types

Size Selection Basics

You must pick the right size for your job. Axial fan sizes change how much air moves. Big fans move lots of air in large places. They work well in factories and tunnels. Small fans fit in tight spots. They help cool machines or small rooms. Longwell has many sizes for different needs. The table below shows how size affects airflow and pressure:

Fan Series | Size Range (mm) | Maximum Airflow (m³/h) | Maximum Pressure (Pa) |

|---|---|---|---|

EFA | Up to 2,240 | Up to 480,000 | 1,800 |

AXL | N/A | Up to 830,000 | 5,000 |

Pick a big fan for a large warehouse. Use a small fan for cooling in a workshop. Always check airflow and pressure before you choose.

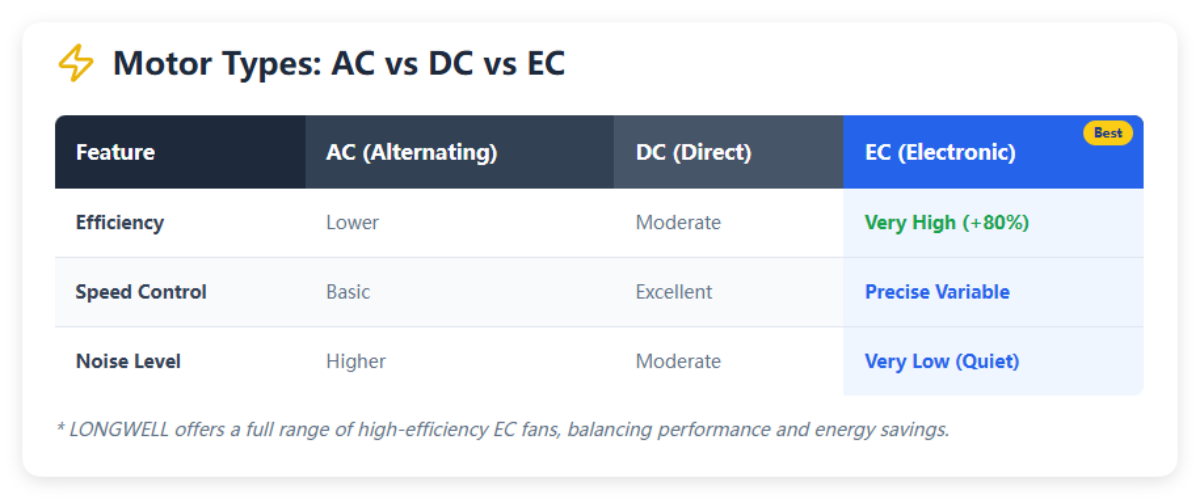

AC, DC, and EC Models

There are three main types of industrial fan. These are AC, DC, and EC models. Each type has its own features. AC fans use alternating current. They give steady airflow. DC fans use direct current. They work well at low speeds. EC fans use both AC and DC. They are very efficient and quiet. The table below helps you compare these fans:

Feature | AC Fans | DC Fans | EC Fans |

|---|---|---|---|

Efficiency | Lower than EC | Moderate | Up to 80% higher than AC |

Speed Control | Basic settings | Excellent at low speeds | Precise variable control |

Pressure Capabilities | Struggles at high pressure | Good at low loads | High static pressure |

Noise Levels | Higher | Moderate | Lower, quieter |

Reliability | Moderate lifespan | Varies | Longer lifespan |

Cost | Lower initial cost | Moderate | Higher initial, lower running |

Pick the fan that matches your power supply and job.

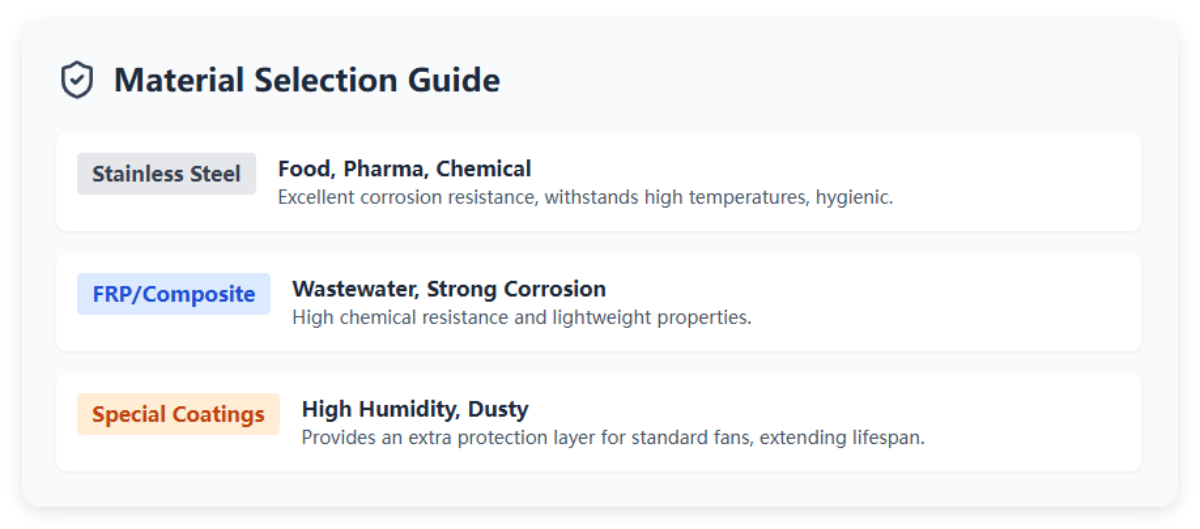

Material & Configuration Choices

The material of the fan is important. It helps the fan last longer and stay safe. Stainless steel does not rust. It works well in food and chemical plants. Aluminum is light and good for medium jobs. FRP and composites resist strong chemicals. They are used in wastewater treatment. Special coatings protect fans in dusty or wet places. The table below shows how materials change performance:

Material Type | Corrosion Resistance | Strength and Durability | Best Applications |

|---|---|---|---|

Mild Steel | Needs coating | Strong, cost-effective | HVAC, general ventilation |

Stainless Steel | Excellent | High temperature, hygiene | Food, pharma, chemical plants |

Aluminium | Naturally resistant | Lightweight, medium-duty | Construction, HVAC |

FRP & Composites | Highly resistant | Durable, lightweight | Chemical, wastewater |

Special Coatings | Extra protection | Extends fan life | Dusty, drying systems |

Longwell has many choices for axial fan sizes and types. You can find the right fan for any job. Use them for cooling electronics or ventilating big spaces.

Key Selection Factors

Performance & Efficiency

You want your industrial axial fan to work well. The main things to check are airflow, maximum airflow, and maximum pressure. These numbers tell you how much air the fan moves. They also show how well the fan pushes air through things. You should look at the volumetric flow rate. This helps you know if the fan is right for your job. Maximum airflow tells you the most air the fan can move in one hour. Maximum pressure shows how hard the fan pushes air through ducts or filters. Brake horsepower measures how fast and strong the fan is. You can see these numbers in the table below:

Metric | Description |

|---|---|

Volumetric Flow Rate | Measures the airflow, usually in CFM, and helps make sure there is enough air in big spaces. |

Maximum Airflow | Shows the most air the fan can move each hour. |

Maximum Pressure | Tells how much resistance the fan must beat to move air, measured in water gauge or Pascals. |

Brake Horsepower | Shows the fan's speed and power, and looks at things like load and air density. |

You should also think about how much energy the fan uses. Fans with EC motors use less energy and save money. DC brushless motors help use less energy and make the fan more reliable. The table below shows how different brands save energy:

Brand/Model | Energy Consumption Features |

|---|---|

Systemair | EC motors help use less energy. |

EBM-Papst | Smart designs help the fan work better. |

General | DC brushless motors make the fan last longer and use less energy. |

If you want the best efficiency, pick a fan that matches your airflow and maximum pressure needs. This helps you save money and get good performance.

Noise & Durability

Noise can change how people feel at work. You should know how loud your fan is. OSHA says the limit is 90 dBA for eight hours. NIOSH says it should be less than 85 dBA. Most industrial fans make noise between 70 and 120 dB. OSHA also says workplaces should keep noise at or below 84 dB for eight hours.

OSHA says the noise limit is 90 dBA for eight hours.

NIOSH says keep noise below 85 dBA for eight hours.

OSHA wants workplaces to keep noise at or below 84 dB for eight hours.

Industrial fans usually make noise from 70 to 120 dB.

Pick a fan that is not too loud. This helps workers stay healthy and pay attention. Durability is important too. Fans made from stainless steel or fiberglass last longer and do not rust. You should check if the fan can work in places with lots of humidity or dust. A strong fan keeps airflow and pressure steady for a long time.

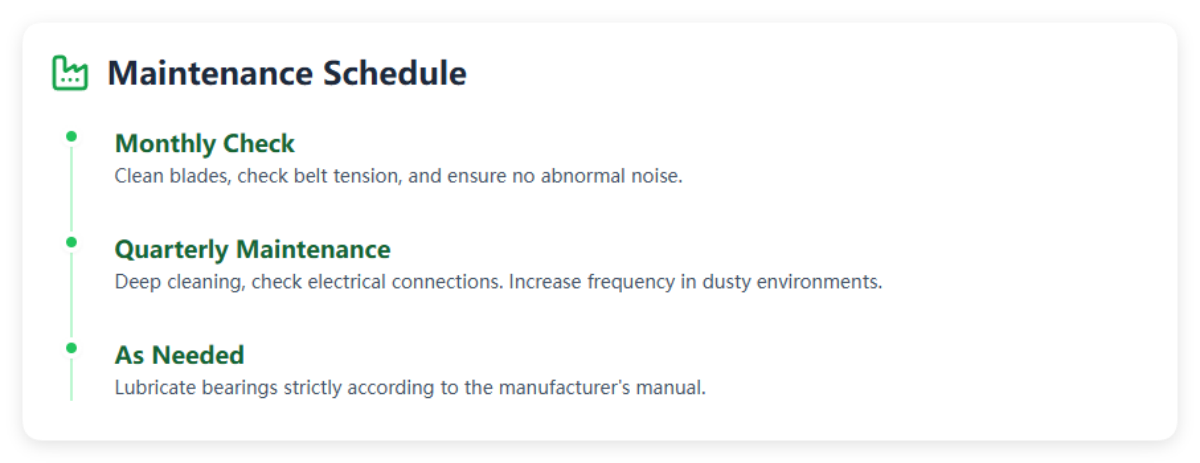

Maintenance & Safety

Taking care of your fan helps it work well. You should clean and check your fan often. Lubricate bearings and motors to keep airflow strong. Check belts every month to make sure they are tight and not worn out. Look for electrical problems like overheating or shaking. The table below shows when to do maintenance:

Maintenance Task | Recommended Interval |

|---|---|

Cleaning and Inspection | Do this often |

Lubrication | Follow what the maker says |

Mechanical Checks | Check every month |

Electrical Maintenance | Do this when needed |

General Maintenance | Every three months (do it more often if there is lots of dust) |

Cleaning and checking often helps the fan work better.

Lubricating bearings and motors makes the fan run smoothly.

Check belts every month to see if they are tight and in good shape.

Look for electrical problems like overheating and shaking.

Safety is very important in dangerous places. You should check for safety certifications. Fans must meet rules for gas and dust zones. The table below explains the zones:

Zone | Gas | Dust | Definition |

|---|---|---|---|

Zone 0 | 1G | 1D | Danger is present for a long time during normal work |

Zone 1 | 2G | 2D | Danger can happen during normal work |

Zone 2 | 3G | 3D | Danger is not likely during normal work |

You need to control the maximum surface temperature of your fan. Each kind of gas or dust has its own temperature where it can catch fire. You must say what the highest safe temperature is for your equipment. This keeps your workspace safe and stops accidents.

Tip: Always pick a fan with airflow, maximum airflow, and maximum pressure that fits your job. This helps you get good performance and stay safe.

Industrial Fan Selection & Comparison

Using a Selection Checklist

You can use a checklist to pick a fan. This makes choosing easier. It helps you focus on what matters most. When you pick a fan, look at these things:

Volume flow rate: Check how fast air moves and the biggest open space.

Airflow density: Know what kind of air you need to move.

Pressure: Find out how much pressure you need for airflow and how much drops across filters or ducts.

Noise level restrictions: Make sure the fan is not too loud for your workplace.

Inlet and discharge configuration: Decide how the fan will connect to your system.

Electrical supply needs: Make sure the fan matches your power source.

Physical size constraints: Measure your space so the fan fits.

Special hazards: Find any risks in your area.

Even flow across aperture: Make sure air moves evenly.

Dwell time: Think about how long air stays in the system.

Tip: A checklist helps you remember important things when picking a fan.

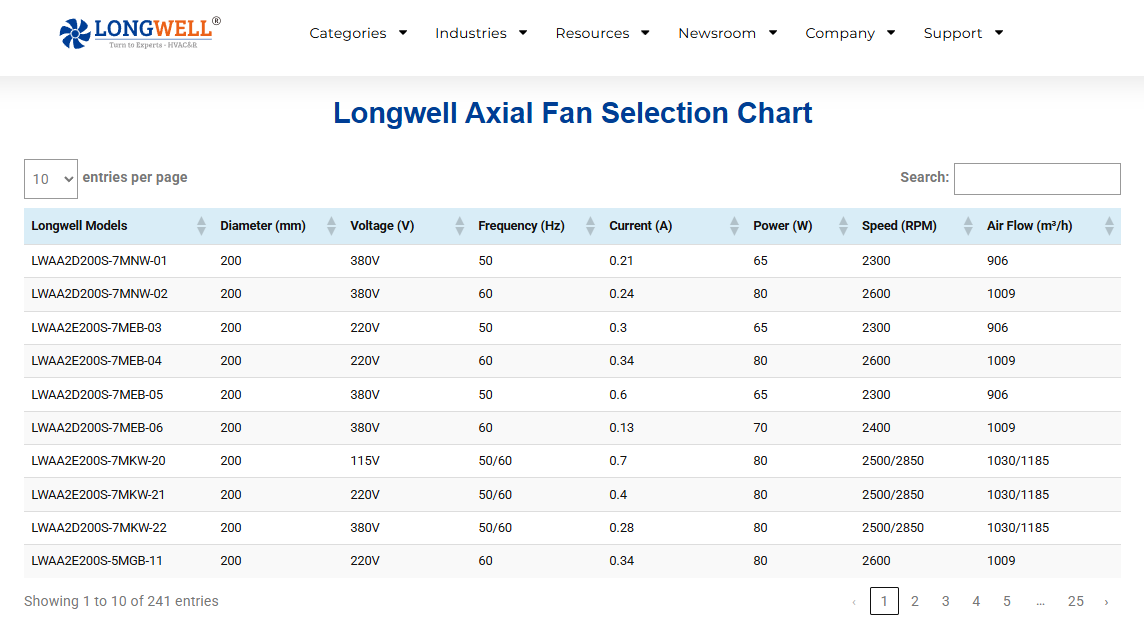

Comparing Longwell Models

Longwell has many axial fan models. They have different airflow, efficiency, and noise levels. You can compare them in the table below:

Fan Type | Airflow Efficiency | Noise Level |

|---|---|---|

Longwell Axial | Up to 85% | Below 25 dB |

Tube Axial | 67% to 72% | Varies |

Vane Axial | Higher than Tube | Varies |

The LWAA4D600B-5MEW-10 model is very quiet. It is good for offices or homes. Longwell fans keep noise low and move air well. These fans use smart controls and electrical protections. This helps save energy and money. It is also better for the environment.

Making the Final Decision

When you finish picking a fan, look at what matters most. The table below shows what to think about:

Criteria | Importance |

|---|---|

Airflow requirements | Keeps cooling and performance good. |

Noise levels | Stops problems in quiet places. |

Energy efficiency | Saves money and helps the environment. |

Customization options | Lets you match the fan to your needs. |

Durability | Makes sure the fan lasts in tough places. |

Material selection | Changes how well the fan works and how long it lasts. |

Blade design | Changes airflow and efficiency. |

Longwell helps you with custom designs and support all day. You can get special designs for your needs. If you need help, Longwell’s team can guide you when picking and installing your fan.

You can pick the best industrial axial fan by following some steps. First, figure out how much airflow you need. Next, check the static pressure for your job. Think about the space and the environment where the fan will go. Make sure the fan’s details match what you need. This helps you save energy and money. Fans with good motors and special blades last longer. They also work better. If you need help, Longwell’s team can give you advice.

Tip: Write down your airflow, pressure, and space needs. Use a checklist to compare fans. This makes choosing a fan easier.

FAQ

What is the difference between axial and centrifugal fans?

Axial fans move air along the axis of the blades. Centrifugal fans push air out from the center. You use axial fans for high airflow and low pressure. Centrifugal fans work better for high pressure and lower airflow.

How do I know what size axial fan I need?

You should measure your room or area. Check how much air you need to move. Look at the airflow rating in cubic feet per minute (CFM) or cubic meters per hour (m³/h). Pick a fan that matches your space and job.

Can I use an axial fan in a humid or dusty environment?

Yes, you can. You should choose a fan made from stainless steel or fiberglass. These materials resist rust and damage. Longwell offers fans with special coatings for extra protection in tough places.

How often should I maintain my industrial axial fan?

You should inspect and clean your fan every month. Lubricate moving parts as the manufacturer suggests. Check belts and electrical parts often. Regular maintenance helps your fan last longer and work better.

What makes Longwell axial fans energy efficient?

Longwell axial fans use EC and DC motors. These motors save energy and lower running costs. Smart controls help you adjust speed and airflow. You get strong performance and less power use.

See Also

Selecting The Ideal Axial Fan For Your Needs In 2025

Choosing Between Duct Fans And Axial Fans For Your Area

Ten Key Industrial Applications For Axial Flow Fans In 2025