Industrial Blower Fan Technology Trends Every Manufacturer Should Know

Manufacturers notice big changes in fan and blower trends for 2025. Centrifugal blower trends are growing fast. The market size will reach $3.5 billion. Emissions are expected to drop by 20% by 2025.

New blowers give better cooling and work better. Centrifugal blower trends also show up to 30% savings with IoT optimization. Cooling systems can save up to 12.1% energy. They can also get a 45% boost in efficiency.

Manufacturers who follow these trends, like those using LONGWELL Industrial Blower Fans: High-Volume High-Pressure Professional Manufacturer, get better cooling, spend less money, and help the environment.

Key Takeaways

Smart industrial blowers have sensors and IoT. These help check how well the blower works. They also help stop breakdowns and save energy.

Energy-efficient motors use less power. Aerodynamic designs help lower costs. These things also make the fan last longer.

High-volume and high-pressure fans meet hard jobs in factories. They also make less noise and help keep people safe.

New materials like ceramic bearings make fans stronger. They help fans work well in hot and rough places.

Custom and modular blower designs give more choices. They make maintenance easier. They also help with sustainability goals.

Technology Integration

Smart Features

Manufacturers want more from industrial blowers now. They do not just want airflow. Smart features are now very important in new blower designs. These features help workers watch how the blower works. They can change settings and get alerts right away. Sensors check things like temperature, vibration, and energy use. This information helps teams find problems early. It also helps them stop expensive breakdowns.

A recent article talks about how fans, filters, and other parts work together. They help with airflow, cooling, and keeping equipment safe. Picking the right airflow technology keeps things safe and efficient. Filters and mounting frames make the system work better. This way, advanced technology is used in industrial blower fans.

Case studies show how smart features help in real life. The table below shows results from different industries:

Location | Smart Feature Used | Benefit Achieved | Quantitative Outcome | ROI / Cost Info |

|---|---|---|---|---|

Amazon Warehouse | HVLS fans | Cooling cost reduction | $12,000 annual savings | N/A |

Auto Parts Factory | HVLS fans | Energy use reduction, improved staff satisfaction | 34% energy reduction, happier staff | ROI in 14 months |

Farms | Smart HVLS fans | Mold risk reduction | 40% reduction in mold risk | N/A |

General HVLS Fans | IoT-enabled smart features | Energy savings and maintenance cost reduction | 25% extra savings over lifetime | Investment recouped in 1-3 years |

These results show that new blower technologies save money and energy. They also make work areas better.

IoT and Automation

IoT and automation have changed how people use industrial blowers. IoT-enabled blowers connect to networks and share data. Control systems get this data. Workers can check how blowers work from anywhere. They can plan repairs and change settings. Automation lets blowers react to changes without people.

Research shows that using supplied air velocity and exhaust velocity together helps a lot. It can make ventilation work 20%-40% better. It can also save up to 70% energy compared to old systems. This proves that new technology in blowers is valuable.

Studies also show IoT and automation help with predictive maintenance. For example:

Study / Source | Focus / Methodology | Statistical Evidence / Outcome |

|---|---|---|

Strauß et al. (2018) | Low-cost sensors, IIoT, machine learning for predictive maintenance | Improved fault detection and maintenance scheduling |

Civerchia et al. (2017) | IIoT monitoring for predictive maintenance | Enhanced monitoring and maintenance effectiveness |

Park et al. (2018) | Real-time fault detection using neural networks | Significant improvement in fault detection accuracy |

Ghosh et al. (2021) | Edge gateway microservices for IIoT monitoring | Better real-time monitoring and data security for predictive maintenance |

These studies show that advanced technology and automation help stop failures. They also lower costs. Companies that use these solutions can do better in a market with new technology and smarter airflow.

Energy Efficiency

Efficient Motors

Manufacturers want to save energy when picking industrial blowers. High-efficiency motors help use less energy. These motors, used in Air Handling Units, can save 20-30% energy. They also move air better and make indoor air cleaner. Many fans have variable frequency drives. These drives change fan speed to match what is needed. This stops wasting energy and helps machines last longer.

High-performance motors are quieter. They break down less and need less fixing. Smart motion controls help motors work better on their own. This means they save more energy and work well, even in hard places. Companies that switch to these motors pay less and use their equipment longer.

Tip: Using high-efficiency motors can help follow rules and may get you energy rewards.

Aerodynamic Design

Better fan wheel and blade shapes make fans use less energy. Engineers use special computer models to shape blades that cut drag and move air better. Studies show that adding winglets or changing blade shapes can make fans 1.8% more efficient. These changes stop air leaks and lower energy use.

New designs look at the whole system. Good ductwork and fewer blocks help air move easily. IoT controls let fans adjust in real time to save more energy. Makers use light materials like carbon fiber to cut friction and wear. These ideas help fans save energy and cost less to run.

Key ways to make blowers use less energy:

Variable-speed drives set fan speed for what is needed.

Aerodynamic blades cut drag.

Good system design lowers resistance.

High-efficiency motors make systems work better.

IoT controls help fans adjust and predict needs.

Light, advanced materials cut friction and loss.

Rules and rewards push companies to use energy-saving fans. Good steps are checking old systems, getting better motors, and making blades better. These moves help companies save energy and reach green goals.

Performance and High-Pressure Solutions

High-Volume Fans

Manufacturers use high-volume fans to move lots of air in big spaces. These fans work well even in tough places. They have special designs and new technology. Engineers use computer models to make impeller blades better. This helps fans save energy and work stronger. Variable frequency drives let workers control fan speed exactly. This can help save up to half the energy. Fans also use noise-reducing materials to make them quieter.

Some main types of high-volume fans are:

Backward-inclined impeller blowers work best for steady airflow. They can be more than 80% efficient.

Forward-curved impeller blowers fit in small spaces and give high pressure. These are good for food and drink factories.

Mixed-flow blowers give both good pressure and high airflow. Water treatment plants often use them.

The table below shows how bifurcated high-volume fans perform:

Performance Metric | Value/Range |

|---|---|

Impeller Diameter | 315 mm to 800 mm |

Flow Rate | Starting from 1123 m³/hour |

Operating Pressure | Starting from 55 Pascals |

Max Transfer Rate | Up to 22,500 m³/hour |

Application Environments | Dust/fume extraction, ventilation |

These features help high-volume fans work well in hard jobs.

High-Pressure Applications

High-pressure industrial blowers are important where strong air is needed. They push air against things that slow it down. These blowers can be made for high heat or to stop leaks and sparks. Many industries use them for dust, smoke, exhaust, and burning air.

Industrial fans last longer and cost less over time than regular fans. In electronics, high-pressure fans keep the right pressure. This helps cool parts and makes them last longer. Some hot air blowers work fast and stay quiet. They are good for medical tools and other special uses.

Note: High-pressure solutions help fans work better, save energy, and stay strong in tough places.

Advanced Materials

Durability

Manufacturers use new materials to make blower fans last longer. Ceramic ball bearings are made from silicon nitride. These bearings help stop electrical corrosion. Corrosion can make blowers break sooner. Ceramic balls are lighter than steel balls. They make less heat and let fans spin faster. This helps fans wear out slower and last longer. NMB Technologies showed ceramic ball bearings work well for inverter cooling.

Ceramic ball bearings help in many ways:

They lower the chance of corrosion.

They make less heat when working.

They let fans run at higher speeds.

They help bearings last longer.

Boyd Corporation uses two-phase heat pipes and vapor chambers. These help move heat away from important parts. They lower heat stress and make fans more reliable. This means blowers can run longer without trouble.

Parameter | Value |

|---|---|

Lifetime | 60,000 hours at 40⁰C |

Frame Material | Die-casting Aluminum |

Blade Material | Plastic |

Bearing Type | Ball |

Fan Type | Axial |

This table shows how new materials help fans last a long time.

Temperature Tolerance

New materials help blowers work in hot places. Die-cast aluminum frames do not bend from heat. Plastic blades keep their shape when air is hot. Ceramic bearings do not get bigger when heated. This helps them keep working well. These things mean fans need less fixing and break less.

Note: Using new materials helps companies spend less on repairs. Fans last longer and work better in hard places.

Noise Reduction

Quiet Operation

Modern factories need quiet fans, especially in places like hospitals and cleanrooms. Engineers use new ways to make axial fans and blowers quieter. They use special fan blades that cut down noise. Sound-absorbing materials help block extra sound. Some systems use active noise control to cancel out noise. Web-based noise monitors with sensors check noise levels all the time. Managers use this data to change settings and follow strict rules.

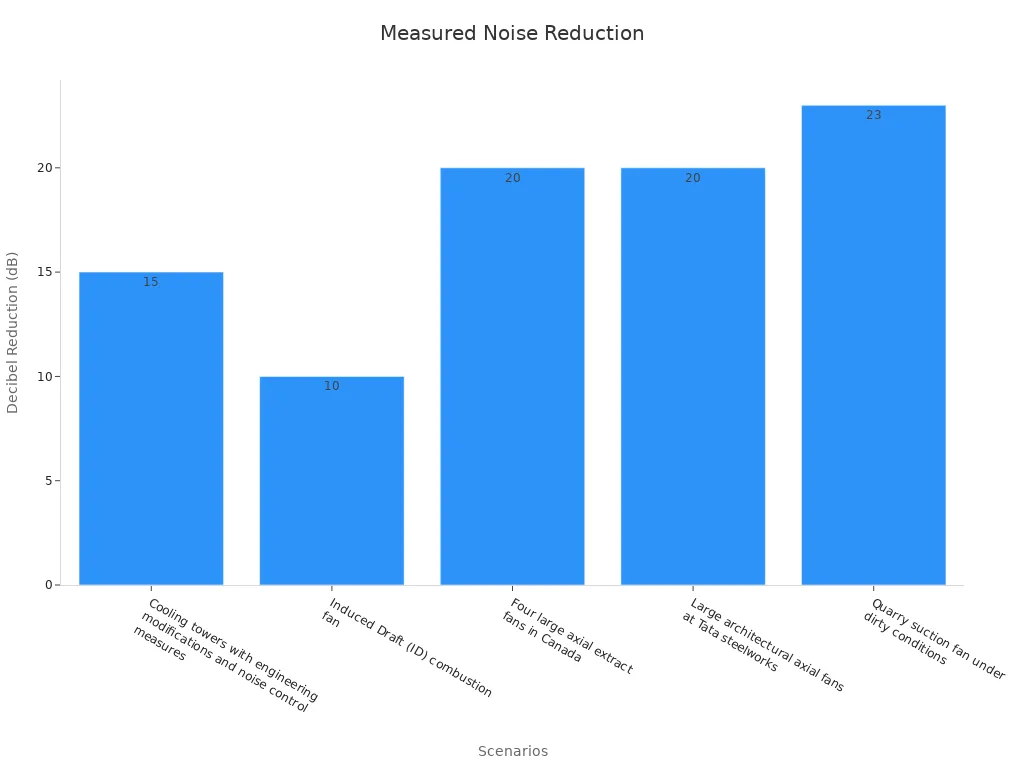

Tests show these changes really help. The table below shows how much noise drops in different places:

Scenario Description | Measured Noise Reduction | Additional Notes |

|---|---|---|

Cooling towers with engineering modifications and noise control measures | 15 dB(A) reduction in overall noise | Reduced running costs; cost-effective solution (~£6k vs £40k conventional) |

Induced Draft (ID) combustion fan | 10 dB drop in noise | Installation took 12 hours; also reduced power consumption |

Four large axial extract fans in Canada | 20 dB attenuation at 100m (99% noise reduction) | Retrofit aerodynamic components; no site visits; improved fan performance; self-financing |

Combustion fan at MDF site with Quiet Fan technology | 22 dB tonal noise reduction; 9 dB(A) overall noise reduction | Installed overnight; low cost; permanent; no efficiency loss; 70-90% lower capital cost than traditional methods |

Large architectural axial fans at Tata steelworks | 20 dB reduction in fan tones | Achieved by slightly slowing fans; no downtime; no efficiency loss; low cost |

Quarry suction fan under dirty conditions | 23 dB tonal noise reduction | No silencers or maintenance needed; ideal for dusty environments; low capital and running costs |

Workplace Benefits

Noise reduction does more than just make things quieter. It helps keep workers safe and comfortable in many ways:

Workers lose less hearing because noise is lower.

Safety gets better since people can talk and hear warnings.

People get less tired and can focus more, so work improves.

Workers are happier and stay at their jobs longer.

Companies meet noise rules more easily and save money.

New features help people talk clearly without taking off hearing protection.

A study from Eindhoven University of Technology found that adaptive sound masking cuts distractions and stress. Workers can focus better and feel less stressed in quieter places.

When companies use quiet fans and noise control, they make work safer and healthier. These changes help blowers work well even in tough places.

Customization and Modularity

Tailored Solutions

Manufacturers want industrial blowers that fit their own needs. Customization lets companies pick features that work best for them. Some industries, like food processing and mining, need special designs to get good results. Companies such as Turbovent Systems make centrifugal blowers for these jobs. This shows more people want custom solutions.

OEMs have seen more orders for radial blade and backward-inclined centrifugal fans. These fans save energy and are easy to add to old systems.

The industrial ventilation fan market will grow by 7% each year until 2035. This is because of more building projects and more machines doing work.

Smart diagnostics and cloud controls are now normal. They help people watch and change how blowers work.

Custom designs help companies follow tough safety and quality rules.

Focusing on custom solutions helps save energy and money. It also makes blowers last longer and work better. The table below shows important ways these solutions help:

Success Metric | Description |

|---|---|

Energy Efficiency | Designs use less energy and lower costs. |

Reliability | Blowers work well even in hard places. |

Customization | Modular designs let you pick features for your job. |

Compliance | They follow strict safety and quality rules. |

Noise Reduction | New noise control makes work quieter. |

Ease of Maintenance | Easy designs mean less downtime and easier fixing. |

Lifecycle Cost Savings | Strong and efficient blowers cost less over time. |

Modular Components

Modular parts have changed how companies use and fix blowers. These designs let people swap out only broken parts. This saves money and cuts down on waste. Modular motors and fan wheels are easy to put in and fix. This lowers wiring costs and makes setup faster. Infinitum’s motors last much longer than old ones.

Modular cooling helps save energy and cuts CO2 emissions.

FanGrid systems use many small fans for better backup and efficiency.

Smart networks let people watch and improve blowers in real time.

Modular designs are small, strong, and quiet.

Parts are tough and made to last a long time.

Modular systems also help the planet. Companies can reuse or recycle parts to make less waste. These systems make it easy to grow and use new technology. This helps companies work better and connect their systems.

Sustainability

Green Materials

Manufacturers now pick green materials for blower fans. They use recycled metals and biodegradable plastics. They also use coatings that do not harm the planet. These choices help cut down on waste. They also support new sustainability trends. Many companies want materials that last a long time. They also want materials that can be recycled later. This means they need fewer new materials. It also means less trash goes to landfills.

Some factories use eco-friendly paints and finishes. These paints do not put many bad chemicals in the air. Companies also choose suppliers who care about the environment. By using green materials, manufacturers show they care about the planet. They help set better rules for the industry.

Using recyclable materials and green practices helps the planet. It also helps companies reach business goals. Companies can meet new rules and what customers want for sustainability.

Emissions Reduction

Factories use a lot of energy and make many emissions. Now, many manufacturers want to lower these emissions. They do this by saving energy. They use blower fans that need less power. Some fans can recover heat that would be wasted. Smart controls help fans slow down when less air is needed.

A study found that using indoor fans at 1.2 m/s can cut greenhouse gas emissions by 76%. This is because fans use much less energy than air conditioners. Workers still feel cool. Companies also pay less for energy.

Sustainability trends include energy recovery systems. These systems catch heat that would be lost. They use it again to save energy. This helps companies get closer to their green goals. It also helps protect the earth for the future.

Sustainability Practice | Impact on Energy Use | Emissions Reduction | Long-Term Benefit |

|---|---|---|---|

Recyclable materials | Lower | Moderate | Less landfill waste |

Energy-efficient blowers | Much lower | High | Lower operating costs |

Energy recovery systems | Lowest | Very high | Improved sustainability |

Manufacturers who follow these trends save energy and cut emissions. They help their business and the planet have a better future.

HVAC Integration

System Efficiency

Factories and big buildings now use blower fans with HVAC systems. This helps them work better and use less energy. With this setup, offices do not need as much compressor cooling. Fans move air to the right spots. This lets buildings set higher temperatures. HVAC systems then use less power. Many places save up to 30% on energy after adding fans to HVAC. Fans also help with natural airflow and cooling with water. This makes the system even more efficient.

Forward-curved blowers push more air and pressure. Better airflow means HVAC machines do not work as hard. This lowers costs to run them. Fresh air keeps moving all the time. This cools rooms and makes the air inside cleaner. Some fans use only 3 watts but still give good airflow. This saves a lot of energy.

HVAC systems now link thermostats, sensors, dampers, fans, and controllers. Sensors watch temperature, humidity, and air quality. They send this info to controllers. Controllers change fan speed and damper position right away. This keeps the system running well. Real-time checks help fix problems before things break. This means less downtime and longer life for machines.

Control Improvements

New control methods have changed how HVAC systems cool and move air. Big, slow fans make people feel cooler, like the room dropped 7 to 11°F. They do this without blowing hard. This lets HVAC systems cool less or sometimes not at all. These fans also mix the air. They make the floor and ceiling almost the same temperature. The difference drops from 20°F to just 1°F. This saves heating energy and makes people more comfortable.

Smart controls use AI and IoT to adjust to people, weather, and changes. In one office, AI helped use less energy but kept rooms at the right temperature. IoT sensors collect data on temperature, humidity, and air quality. This helps the system control things better all the time. Machine learning can guess how much heating or cooling is needed. It sets the best temperatures and finds problems early. These upgrades save 20% to 50% energy, make rooms nicer, and stop breakdowns.

Tip: Using blowers with smart HVAC controls gives better cooling, saves energy, and makes air cleaner in factories and offices.

Longwell Industrial Blower Fans: High-Volume High-Pressure Professional Manufacturer

Longwell industrial blower fans: high-volume high-pressure professional manufacturer is a top company in the fan world. They make special fans for tough jobs. Their high-volume, high-pressure technology helps many important businesses. Longwell industrial blower fans: high-volume high-pressure professional manufacturer gives strong performance, saves energy, and answers customers fast.

Product Range

Longwell industrial blower fans: high-volume high-pressure professional manufacturer has many different fans. They sell EC, DC, and AC centrifugal fans, axial fans, and special ventilation fans. Each fan uses smart motor technology for good airflow and to save energy. The company also makes fans for big buildings and farms. This means they have fans for almost any job.

Product Category | Industry Applications and Features |

|---|---|

EC/DC/AC Centrifugal Fans | Used in factories, offices, and hospitals; have EC motors for saving energy and controlling airflow. |

EC/DC/AC Axial Fans | Used for ventilation, air conditioning, and cooling; move lots of air and save energy. |

Industrial Ventilation Fans | Include exhaust and supply fans; made to be strong, reliable, and last long in factories. |

Commercial Building Fans | Good for offices, malls, hotels, and sports places; quiet, efficient, and help keep indoor air clean. |

Agricultural Fans | Used in greenhouses and animal barns; help plants grow and keep animals comfortable. |

Industry Applications

Longwell industrial blower fans: high-volume high-pressure professional manufacturer helps many types of businesses. Their fans are used in HVACR, wind energy, building ventilation, medical machines, data centers, and heating. You can also find their fans in home appliances and special factory jobs. Longwell industrial blower fans: high-volume high-pressure professional manufacturer can make custom fans for data centers and trains.

People trust Longwell industrial blower fans: high-volume high-pressure professional manufacturer because they are fast, affordable, and high quality.

The table below shows what makes Longwell special:

Performance Metric / Factor | Description |

|---|---|

Energy Efficiency Improvement | EC axial fans save 20-30% energy by using special computer tools to design better airflow. |

Global Certifications | Has ISO 9001, ISO 14001, ETL, CE, and RoHS certifications to show their products are safe and high quality. |

Industry Recognition | Called a “Core Strategic Supplier” by top customers, showing they are trusted and respected. |

Customization Capabilities | Can make special fans for hard jobs like data centers and trains, so their fans fit many needs. |

Cost-Performance Advantage | Sells fans at better prices and delivers faster than some European and American companies. |

Longwell industrial blower fans: high-volume high-pressure professional manufacturer keeps leading the way. Their fans are smart, save energy, and work well for today’s factories.

Manufacturers get many good things from using new blower fan trends. Smart features, energy-saving motors, and strong new materials help fans work better and cost less. Green choices and modular designs help companies follow tough rules.

Check your current systems to see if you can upgrade.

Teach your team about new technology.

Work with trusted suppliers to get custom solutions.

If you keep learning and act early, you can stay ahead in a market that changes fast.

FAQ

What are the main benefits of using smart industrial blower fans?

Smart blower fans let you watch how they work right now. You can control them from far away. They also help fix problems before things break. These features help teams stop long breaks, use less energy, and keep systems working well.

How do energy-efficient motors impact operating costs?

Energy-efficient motors use less electricity. They also need less fixing. This helps companies save money on power bills. It also makes machines last longer.

Can manufacturers customize blower fans for unique applications?

Yes. Many suppliers let companies pick what they need. You can choose special features, materials, and sizes. This helps the fan fit your job.

Why should manufacturers consider modular blower fan designs?

Modular designs make it easy to swap out parts fast. You can also upgrade fans without trouble. This helps stop long breaks, lets you grow later, and keeps repair costs low.

See Also

Selecting The Best Centrifugal Fan For Your Needs 2025

A Guide To Picking The Perfect Cross Flow Fan