What are Longwell EC fans and their main features

A longwell ec fan uses advanced electronically commutated (EC) motor technology. This technology combines brushless DC motors and integrated electronics for precise speed control. These fans help lower energy use by about 25-30% compared to traditional AC fans. Many industries choose longwell ec fan models because they run quietly and support smart control systems. The growing demand for energy-efficient cooling drives their popularity in HVAC, industrial, and data center applications.

Key Takeaways

Longwell EC fans use advanced motors that save up to 30% energy compared to traditional fans, helping reduce electricity bills.

These fans run quietly thanks to aerodynamic blades and precise speed control, making them ideal for noise-sensitive places.

Smart control systems allow real-time monitoring and remote adjustments, improving efficiency and reliability.

Durable materials and easy maintenance extend the fans' lifespan and lower repair costs.

Longwell EC fans suit many uses, including HVAC, industrial ventilation, process cooling, and quiet environments, offering strong performance and cost savings.

Overview

What Is a Longwell EC Fan

A longwell ec fan stands out in the market because of its advanced design and technology. These fans use a special type of motor called an electronically commutated (EC) motor. This motor blends the best parts of AC and DC power, which helps the fan save up to 50% more energy than traditional fans. Many users choose these fans for their precise speed control. This feature allows the fan to adjust airflow in real time, which is helpful in places where airflow needs change often.

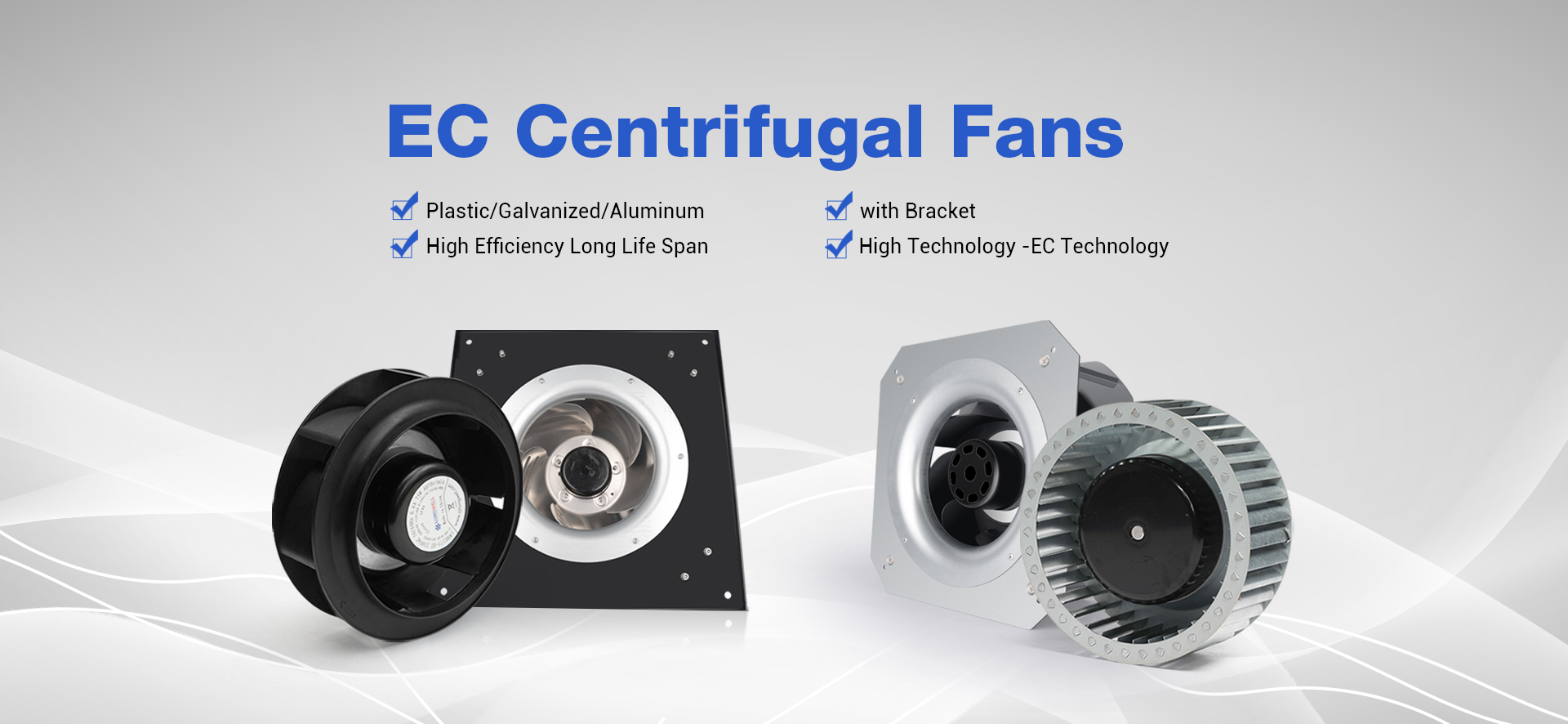

The design of the fan blades also makes a difference. Longwell EC fans use aerodynamic impellers that push air with high pressure but keep noise low. The built-in control system, called a PCB, lets users monitor speed, check for faults, and connect the fan to building management systems. These fans come in different materials, such as metal, plastic, or aluminum alloy, so they can work in many environments. People find them easy to install and maintain. Many customers also praise the company’s technical support and after-sales service.

Tip: Longwell EC fans offer customization options to fit special needs in different industries.

EC Motor Technology

The EC motor inside a longwell ec fan uses modern technology to improve performance. The motor has a built-in electronic controller that replaces old-fashioned brushes. This controller manages how the motor turns, which makes the fan last longer and need less maintenance. The rotor uses permanent magnets, which help cut down on wasted energy.

The motor works by switching the direction of the electric current with electronics instead of mechanical parts. This process, called electronic commutation, makes the motor more efficient and reliable. EC motors allow for fine control over speed and torque, so the fan can run exactly as needed.

Here is a quick comparison between EC motors and traditional AC motors:

Feature | EC Motor (Longwell EC Fans) | Traditional AC Motor |

|---|---|---|

Energy Consumption | About 20% lower | Higher |

Efficiency | Up to 90% | Up to 75% |

Airflow Performance | 30% higher at 3900 RPM | Standard at similar RPM |

Operational Cost | Lower | Higher |

EC motors also run more quietly and need less upkeep. Although the initial cost may be higher, the savings over time make them a smart choice for many users.

Features

Energy Efficiency

Longwell EC fans stand out for their impressive energy savings. The company uses a self-developed aerodynamic simulation and CFD optimization platform to improve efficiency by 20-30%. In commercial HVAC systems, models like the LWBE3G450-188PT-09 have shown up to 30% energy savings each year. This reduction means lower electricity bills and less strain on power resources.

Longwell EC axial fans achieve 20-30% energy efficiency improvement.

The fans hold global certifications such as ISO 9001, ISO 14001, ETL, CE, and RoHS.

These certifications focus on quality and environmental standards.

Note: Longwell EC fans do not have specific energy efficiency labels like AMCA, but their certifications show a commitment to quality and sustainability.

The company also meets international environmental standards, including ISO 14001 and ISO 50001. These standards prove that Longwell focuses on green technology and energy management. The use of energy-saving materials and processes helps reduce emissions and supports a cleaner environment.

Quiet Operation

Longwell EC fans operate quietly, making them suitable for noise-sensitive areas. For example, the 200mm EC axial fan produces about 60 dBA during operation. This level is similar to a normal conversation, so the fan does not disturb people nearby.

Several design features help keep noise low:

Advanced EC motor design allows precise speed control, which reduces noise.

Optimized impeller blades use aerodynamic shapes to minimize sound while moving air efficiently.

The intelligent PCB control system provides stable operation and further lowers noise.

These features make the longwell ec fan a good choice for offices, hospitals, and other places where quiet matters.

Smart Controls

Smart control systems add another layer of value to Longwell EC fans. These systems allow real-time monitoring, precise adjustments, and remote control. Users can manage fan performance from a distance, which improves efficiency and flexibility.

Real-time performance monitoring and remote control.

Parallel fan design offers redundancy, so if one fan fails, others keep working.

Upgrades in office buildings have shown up to 40% energy savings and 30% noise reduction.

Data center upgrades have achieved 35% energy savings, 25% fewer failures, and 10% lower maintenance costs.

Longwell EC fans support automation and remote monitoring. This means building managers can check fan status and adjust settings without being on-site. These smart controls help reduce energy use, lower noise, and improve reliability.

Durable Design

Longwell EC fans use strong materials and smart construction methods to ensure a long service life. The company often uses steel and stainless steel for fan blades. These materials resist corrosion and provide strength. For lighter-duty needs, aluminum and composite materials offer a balance of cost and performance.

Steel and stainless steel blades for strength and corrosion resistance.

Aluminum and composite options for lighter applications.

Secure mounting and correct ductwork sizing help reduce vibration.

Routine maintenance, such as cleaning and lubrication, keeps fans running well.

The company also follows strict quality management practices. Certifications like ISO 9001 and ISO 14001 show a focus on reliability and environmental care. Manufacturing uses eco-friendly materials and energy-saving technologies to lower carbon emissions.

Tip: Regular maintenance, such as cleaning blades and checking bearings, extends the life of any fan.

Benefits

Cost Savings

Longwell EC fans help users save money in several ways. The advanced EC motor technology uses less electricity than traditional fans. This lower energy use leads to smaller utility bills over time. Many businesses see a return on investment within a few years because of these savings. The fans also have a long lifespan, which means fewer replacements and less spending on new equipment. Smart controls allow users to adjust fan speed to match real needs, avoiding wasted energy and extra costs.

Tip: Energy-efficient fans can reduce annual operating costs by up to 30% in commercial buildings.

Reliability

Reliability stands out as a key benefit of these fans. Several design features support dependable operation:

EC motors combine AC and DC technology for stable performance and high energy efficiency.

Electronic speed control allows precise airflow adjustments, improving system performance.

Aerodynamic impellers deliver strong airflow with low noise, even in tough conditions.

Integrated PCB control systems monitor speed, temperature, and faults, preventing downtime.

Durable materials like aluminum die-cast housings and high-strength iron impellers add strength.

Protection ratings such as IP42, IP44, and IP54 shield the fans from dust and moisture.

Ball and sleeve bearings extend operational life, with some models running over 60,000 hours at high temperatures.

Modular design makes installation and repairs easier, reducing the risk of long outages.

These features ensure the fans work well in many environments, from offices to factories.

Easy Maintenance

Maintenance for these fans is simple compared to many traditional models. The modular design allows users to replace parts like blades or motors without special tools. Ball bearings reduce the need for frequent lubrication and support longer service intervals. After-sales support includes free replacement parts and video guides, making repairs less stressful.

Fan Type | Maintenance Procedures | Maintenance Complexity Compared to Traditional Fans |

|---|---|---|

Centrifugal Fans | Regular checks on impeller and motor; lubrication of moving parts | More complex; requires frequent and detailed maintenance |

Axial Fans (including EC fans) | Regular cleaning of blades; motor wear checks | Simpler; generally less maintenance due to simpler design |

Customization options and warranty coverage further ease the process. Users can select the right materials and configurations for their needs, making upkeep straightforward and cost-effective.

Applications

HVAC Systems

Longwell EC fans play a vital role in modern HVAC systems. They help buildings maintain comfortable temperatures and healthy air. These fans optimize airflow, which reduces the workload on heating and cooling equipment. Lower energy use means smaller utility bills. Smart controls let building managers adjust fan speed and monitor performance. The fans also improve indoor air quality by removing pollutants and controlling humidity. This creates a healthier environment for people inside.

Benefit Category | Description |

|---|---|

Energy Efficiency | Optimized airflow reduces system workload, lowering energy consumption and utility costs. |

Indoor Air Quality | Proper ventilation removes pollutants, allergens, odors, and controls humidity for healthier air. |

Equipment Longevity | Reduced system pressure and workload extend lifespan of fan blades and air handlers. |

Smart Controls Integration | Use of sensors and controls further optimizes airflow and energy use. |

Industrial Ventilation

Factories and workshops need strong ventilation to keep air clean and safe. Longwell EC fans meet these needs in many scenarios. In industrial workshops, they provide energy-efficient ventilation and smart speed control. Chemical plants use these fans for emergency ventilation, quickly removing hazardous gases. Commercial buildings upgrade old systems with these fans to improve air quality and comfort. Cleanrooms rely on precise control to maintain strict cleanliness standards. Subway stations and tunnels use large-capacity fans for continuous air removal and emergency smoke extraction.

Industrial Ventilation Scenario | Description and Ventilation Requirements | Role of LONGWELL EC Fans and Features |

|---|---|---|

Industrial Workshops | Air-exchange rates vary by process: 3-6 exchanges/hour for low heat/pollutants; 10+ for high heat/dust areas. | EC fans provide energy-efficient ventilation, meeting GB 50019-2015 standards with smart speed control to optimize air quality and energy use. |

Emergency Ventilation in Chemical Plants | Rapid increase of air-exchange rate (up to ~20 times/hour) to expel hazardous gases during incidents. | LONGWELL centrifugal blowers with EC motors and smart controls quickly ramp up airflow to remove toxic gases, ensuring worker safety. |

HVAC Upgrades in Commercial Buildings | Retrofit old systems to meet modern air quality standards (~6 air exchanges/hour), reduce CO₂, and improve comfort. | Replacement with LONGWELL EC axial and cross-flow fans plus smart controls reduces energy consumption by ~20%, maintaining fresh air efficiently. |

Cleanroom Environments (Electronics, Medical) | High air-exchange rates (~25 per hour) to maintain ISO 7/Class 10,000 cleanliness, stable temperature, humidity, and pressure. | LONGWELL centrifugal fans with EC motors provide precise variable-frequency control, ensuring compliance and reducing power use by ~20%. |

Subway Stations and Tunnels | Continuous removal of CO₂ and heat; emergency smoke extraction during fires with high-temperature resistance. | LONGWELL large-capacity axial fans with reinforced blades operate stably under normal and emergency conditions, ensuring safety and ventilation. |

Process Cooling

Manufacturing environments depend on process cooling to keep machines and products at safe temperatures. Longwell EC fans improve cooling efficiency in several ways:

EC motors allow precise speed control, so fans run efficiently even at lower speeds.

Fans produce less heat, which reduces the cooling load on HVAC systems.

Speed adjusts dynamically based on air demand, making them ideal for cooling towers and process chillers.

Efficient dust and fume removal improves air quality and workplace health.

Brushless motors reduce friction and wear, leading to longer life and less maintenance.

Fans use less power than traditional models, saving energy and lowering costs.

High efficiency across a wide speed range ensures optimal airflow and temperature control.

Noise-Sensitive Areas

Some places need quiet operation, such as hospitals, libraries, and offices. Longwell EC fans work well in these environments. Their advanced motor design and aerodynamic blades keep noise levels low. Smart controls help maintain quiet by adjusting speed as needed. People can work, rest, or recover without loud background sounds. These fans support comfort and concentration in noise-sensitive spaces.

Tip: Choosing a longwell ec fan for quiet areas helps maintain a peaceful atmosphere and supports productivity.

Why Choose Longwell EC Fan

Comparison to AC Fans

Longwell EC fans offer several advantages when compared to traditional AC fans. Many users notice these differences in both performance and cost over time.

EC motors reach up to 90% efficiency. Smart controls help save energy and lower operating costs.

AC motors are known for durability and low maintenance. Their simple design means fewer breakdowns.

The market now prefers EC motors. Their energy efficiency and variable speed control reduce electricity use and maintenance needs.

EC fans often provide a lower total cost of ownership, especially in modern HVAC and industrial settings.

AC motors still offer value with their durability and simple parts, which can mean less downtime.

EC motors meet new environmental rules and rising energy costs. Their smart features add more value for long-term use.

Performance tests show clear differences between the two fan types:

Performance Aspect | Longwell EC Fans (Brushless EC Motors) | Traditional AC Fans (Brush Motors) |

|---|---|---|

Noise | Significantly reduced due to absence of brushes and friction | Higher noise from brush friction |

Longevity | Up to 30% longer lifespan with less maintenance | Shorter lifespan due to brush wear |

Energy Efficiency | Up to 20% more efficient, converting more electrical power to airflow | Less efficient, more energy wasted |

Airflow | Centrifugal blowers deliver more airflow with less power | Less airflow for the same power consumption |

Note: EC fans help users save money and energy while providing quieter and longer-lasting performance.

Unique Advantages

Longwell EC fans stand out for their real-world results and customer satisfaction. Many companies trust these fans for important projects.

Large factories use Longwell EC fans for ventilation upgrades. These projects show reliability and strong performance.

The US Grain Silo anti-mold project used these fans to prevent mold and save millions of dollars.

Dutch greenhouses improved their ventilation during the energy crisis. They chose Longwell EC fans for energy savings and smart controls.

Modern farms in Europe use these fans to balance energy savings and animal health.

The company uses advanced brushless motors and aerodynamic blades. These features increase efficiency and reduce noise.

Certifications like ISO9001, CE, RoHS, and UL prove the quality and safety of these fans.

Customers receive expert support in many languages for choosing, installing, and maintaining their fans.

Tip: Many users choose Longwell EC fans for their proven energy savings, quiet operation, and strong technical support.

Industry experts highlight several key strengths of Longwell EC fans:

Superior energy efficiency and high air volume for industrial cooling.

Advanced EC motor technology ensures precise control and long lifespan.

Proven reliability and scalability, even in large-scale projects.

Low noise, easy installation, and strong global support.

Feature | Longwell Fans | Competitors |

|---|---|---|

Low | Medium-Low | |

Lifespan | Long | Medium-Long |

Maintenance | Low | Medium |

Price Level | Medium | Low-High |

Readers can explore the Longwell website for research articles, product guides, and technical support. These resources help users make informed decisions about upgrading to advanced, energy-saving fans.

FAQ

What makes Longwell EC fans different from regular fans?

Longwell EC fans use advanced motors with built-in electronics. These motors save more energy and run more quietly than regular fans. Users can also control the speed easily.

Can Longwell EC fans work in wet or dusty places?

Yes, many Longwell EC fans have protection ratings like IP54. This rating means the fans resist dust and water. They work well in factories, kitchens, and outdoor areas.

How do users control the speed of a Longwell EC fan?

Users can adjust the speed with smart controls. Some models connect to building systems or use remote controls. This helps match airflow to the needs of the space.

Do Longwell EC fans need a lot of maintenance?

No, these fans need less maintenance than traditional fans. The brushless motors last longer. Users only need to clean the blades and check parts sometimes.

Are Longwell EC fans good for saving money?

Yes! Longwell EC fans use less electricity. Many businesses see lower energy bills. The fans also last longer, so users spend less on replacements.

See Also

Ways Longwell Centrifugal Fans Deliver Exceptional Energy Savings

Benefits Of Selecting Longwell Forward Centrifugal Fans For Efficiency

Key Industrial Blower Fan Innovations All Manufacturers Must Understand

Comprehensive Guide To Cross Flow Fan Efficiency In Ventilation Systems

Tips For Selecting The Ideal Cross Flow Fan For Applications