What Is a Blower Fan and How Does It Work

A blower fan moves air with a spinning impeller. Blower fans push air in one set direction. This makes them different from regular fans. Most blowers help cool, dry, or move air in many places. They work in homes, cars, and factories. Blower fans can use energy very well. For example, a 25-inch blower can reach 68% top efficiency. If you know how a blower controls air, you can make better choices. This helps save energy and feel more comfortable.

Key Takeaways

Blower fans move air in one direction with a spinning impeller. This makes them work better than normal fans.

Picking blower fans with ECM motors uses less energy. These motors keep airflow steady, even if filters or ducts slow it down.

There are different blower types, like centrifugal and axial. Each type is good for different jobs, like high pressure or moving lots of air quietly.

Cleaning and checking blower parts often helps them work better. This also makes them last longer and saves energy.

Blower fans are important in homes, cars, and factories. They help with comfort, safety, and moving air well.

Blower Fans Explained

What Is a Blower

You can think of a blower as a special kind of fan. Blowers use a spinning part called an impeller to move air. Unlike regular fans, blowers push air in a set direction and often create higher pressure. This makes them useful for moving air through ducts or tight spaces. Blowers work in many places, such as homes, cars, and factories. You will find that blowers help with air circulation, cooling, and drying.

Researchers have studied blowers by looking at their main parts and how they work. A blower has an impeller, a casing, and a blower motor. The impeller spins inside the casing, and the blower motor provides the power. Some studies use special tools to measure how fast the impeller spins and how much the blower vibrates. These tests show that blowers are rotary machines. They move air by giving it energy through spinning parts. You can see blowers in action when you use a hair dryer, a car heater, or a home furnace.

Blower fans stand out from traditional fans because of their efficiency. Studies show that blower fans with electronically commutated motors (ECMs) keep airflow steady even when pressure changes. These blower fans use less power, especially at low resistance. Traditional fans with permanent split capacitor (PSC) motors lose airflow and use more energy when pressure rises. ECM blower fans can save up to 45% more electricity at low resistance compared to PSC fans. This means you get better airflow and lower energy bills with ECM blower fans.

Blower Fan Parts

A blower fan has several important parts. Each part works together to move air and keep the blower running smoothly. Here is a table that shows the main parts and what they do:

Part Name | What It Does |

|---|---|

Impeller | Spins to move air and create pressure |

Blower Motor | Powers the impeller and controls its speed |

Casing | Holds the impeller and directs the airflow |

Electrical Connectors | Link the blower motor to the power source |

Resistors | Help control the speed of the blower motor |

Gears and Transmission | Transfer power from the blower motor to the impeller |

Safety Components | Protect the blower from overheating or damage |

You can find these parts listed in catalogs, guides, and product brochures. Some guides show you how to connect wires or replace parts. Others help you pick the right blower fan for your needs. Testing services check that each part works well and meets safety standards. You will also see different types of blowers, such as centrifugal blowers, axial blowers, and custom fans. Each type uses these basic parts but may have special features for certain jobs.

How Blower Fans Work

When you turn on a blower fan, the blower motor starts the impeller spinning. The impeller does not just push air forward. Instead, it gives energy to the air particles. You can picture this like a golf club hitting a ball. The spinning impeller stores energy and then transfers it to the air. This action creates a pressure difference. Air moves from high pressure to low pressure, and this keeps the airflow going.

The design of the impeller changes how the blower works. For example, a Roots blower uses special blades that trap and release air as they spin. The speed of the impeller and the space between the blades and the casing affect how much air the blower moves. If the impeller spins faster, the blower creates more airflow. If the space between the blades and the casing is small, the blower can make higher pressure.

You will notice that different impeller shapes also change how the blower fan works. Forward curved impellers are compact but less efficient. Backward curved impellers are larger and more efficient. Radial impellers create higher pressure. The casing, often shaped like a shell, helps guide the air and reduce friction. The blower motor controls how fast the impeller spins. More motor poles mean slower spinning at the same power supply frequency.

Blower fans do not just create airflow by spinning. They set up a pressure gradient that keeps air moving. This is why blower fans can push air through filters, ducts, or vents, even when there is resistance. ECM blower motors help blower fans keep steady airflow, even if the filter gets dirty or the duct is long. PSC blower motors lose airflow when resistance goes up. This makes ECM blower fans better for keeping optimal airflow in your home or workplace.

Tip: If you want the best performance from your blower fan, choose one with an ECM blower motor. You will get steady airflow and save energy, even if your system faces extra resistance.

Types of Blower Fans

Centrifugal Blower Fans

Centrifugal blower fans are used in many factories and big buildings. These blowers have an impeller that spins and pushes air out from the middle. This makes high pressure. The design lets you move air through ducts and filters, even if there is resistance. Centrifugal blowers are good for collecting dust, moving materials, and letting air flow in tough places.

Here is a table that shows how you can check how well centrifugal blower fans work:

Performance Metric | Description | Industry Standard or Data |

|---|---|---|

Airflow | How much air the blower moves | Measured with flow meters |

Pressure Rise | Pressure increase from the blower | Up to 10 inwg |

Power Consumption | Energy used by the blower | Used to check efficiency |

Overall Efficiency | Output vs. input energy | Over 85% for top blowers |

Noise Level | Sound during operation | Can be 75 dB or higher |

Energy Savings | Energy saved with new technology | Up to 50% with VFDs and upgrades |

Note: Centrifugal blowers can help you use less energy. Some models have variable speed drives. These can lower power use by up to 50%.

Axial Blower Fans

Axial blower fans move air in a straight line, along the axis. People use these fans to cool big areas or bring fresh air into rooms. Axial blowers are best when you need to move lots of air but do not need high pressure. They are smaller and quieter than centrifugal blowers.

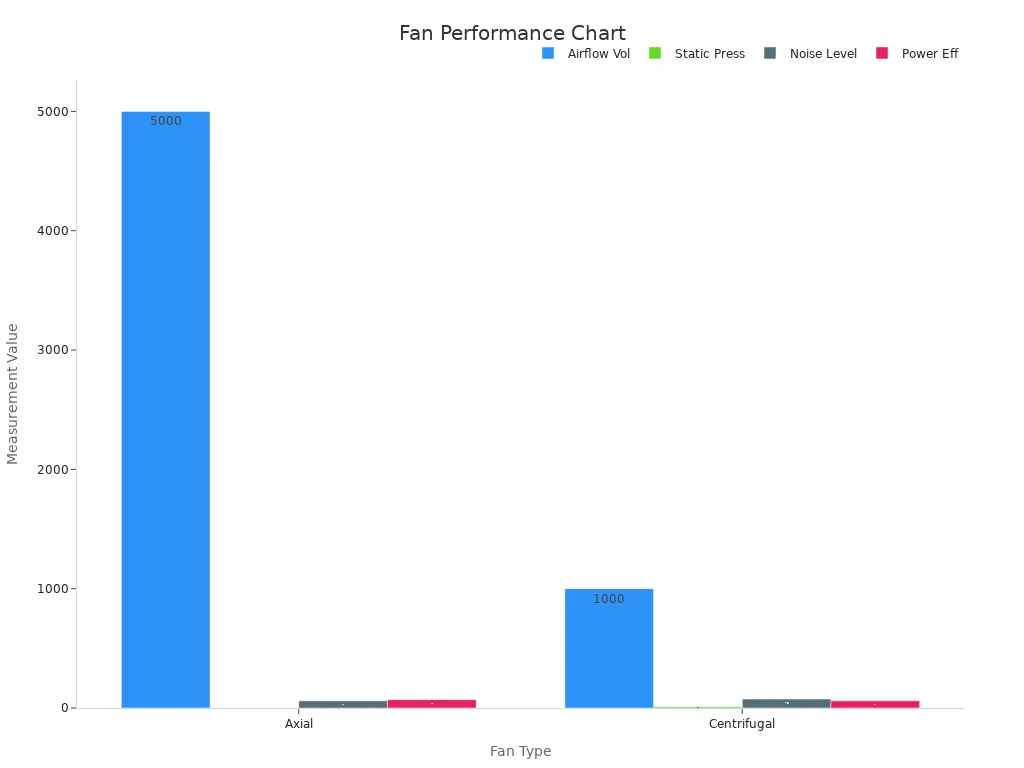

Here is a chart that compares axial and centrifugal blower fans:

You can see that axial fans move more air, up to 5,000 CFM. But they make less pressure. Centrifugal blowers move less air, about 1,000 CFM, but can handle higher pressure. Axial blowers are also quieter. This makes them good for offices or cooling electronics.

Other Blower Types

There are other blower types for special jobs besides centrifugal and axial blowers. Mixed flow blowers have features from both main types. Bladeless fans use new ideas to move air quietly and safely. Some blowers are made for data centers, clean rooms, or labs. These blowers help control air quality and temperature very well.

The worldwide market for fans and blowers was about $8.2 billion in 2024. It may grow to $10.8 billion by 2030.

You will find blowers in building sites, mines, food factories, and chemical plants.

Companies like ABB, Greenheck, and Howden make many blower types for different jobs.

New blowers use IoT technology for remote checks and better energy savings.

Tip: If you need a blower for a special job, pick one with features like noise control, variable speed, or smart controls. These choices help you follow safety and energy rules.

Blower Motor Basics

How Does a Blower Motor Work

You might wonder, how does a blower motor work? The blower motor is the heart of any blower. It powers the impeller, which spins and moves air through the system. When you turn on your HVAC, the blower motor starts right away. It uses electricity to create motion. This motion turns the impeller inside the blower. As the impeller spins, it increases air pressure and pushes air in one direction.

Blower motors come in different types. Some use brushless DC motors, while others use AC motors. Modern blower motors often use sensorless control. This means they do not need physical sensors to know the rotor’s position. Instead, they use electronic control to start and run smoothly. This helps the blower motor function with less noise and more reliability. The Allegro MicroSystems technical document explains that these advanced controls help prevent problems like reverse rotation and slow startup. You get fast and stable operation every time you use your blower.

The blower motor resistor is another key part. It helps control the speed of the blower motor. When you adjust the fan speed in your car or home, the blower motor resistor changes the amount of electricity reaching the motor. This lets you pick the airflow you want.

Tip: If your blower only works on one speed, the blower motor resistor might need replacing.

HVAC Blower Motor

The hvac blower motor plays a big role in your comfort. In an hvac system, the blower motor moves air through ducts, vents, and filters. You feel warm or cool air because the hvac blower motor pushes it into your rooms. The blower motor function is to keep air moving, even when filters get dirty or ducts are long.

You will find two main types of hvac blower motors. The first is the permanent split capacitor (PSC) motor. The second is the electronically commutated motor (ECM). ECM motors save more energy and keep airflow steady. Many new hvac systems use ECM motors for better performance.

The blower motor resistor also helps in hvac systems. It lets you set different fan speeds. If your hvac blower motor stops working at certain speeds, check the blower motor resistor first.

Here is a quick table to show how the hvac blower motor works in your hvac system:

Part | What It Does |

|---|---|

Blower Motor | Powers the blower and moves air |

Blower Motor Resistor | Controls the speed of the blower motor |

Impeller | Spins to push air through the system |

HVAC System | Uses the blower to heat or cool your space |

Engineering studies show that blower motors use impellers or rotors to increase air pressure and velocity. New designs, like variable-speed ECMs and VFDs, help save energy and improve control. Some blowers even use magnetic bearings for less maintenance.

Note: If you want your hvac system to run well, keep the blower motor and blower motor resistor in good shape. Regular checks help you avoid sudden breakdowns.

Uses for Blower Fans

Home Applications

You can find a blower in many places at home. The blower motor in your furnace or air conditioner moves air through the hvac system. This helps keep each room at the right temperature. When you use your dryer, a blower pushes hot air to dry clothes faster. Some vacuum cleaners use a blower motor to make strong suction. Air purifiers also have blowers that move air through filters to clean it.

Tip: If your house feels stuffy or some rooms are too hot, check if your blower motor needs cleaning or fixing.

Blowers work quietly and help you feel comfortable. They help you breathe cleaner air and keep your machines working well. You might not see the blower, but it is important for your comfort every day.

Industrial Uses

Factories and big buildings need blowers for many jobs. The blower motor in these places must work hard and keep air moving in tough spots. You can see blowers in chemical plants, food factories, and mines. The Industrial Fans and Blowers Market Report 2025 says that industries like petrochemicals, wood, and car makers all use blowers.

Blowers help control dust and pollution to make work safer.

They keep machines cool and help control temperature in hvac systems.

In mines, blowers bring in fresh air and take out bad gases.

Many blowers are small, so they fit in tight spaces and are easy to fix.

Industrial blowers often use advanced blower motors to save energy and last longer. Many factories now use smart blowers with IoT to watch how they work and save power.

Automotive Blower Fans

Your car uses blowers to keep you safe and comfortable. The blower motor in your car’s hvac system moves air through vents. This lets you control the temperature inside the car. It keeps you cool in summer and warm in winter. Blowers also help cool the engine and move exhaust gases.

Application Area | Role of Blower Fan |

|---|---|

HVAC System | Keeps cabin air at the right temperature |

Engine Cooling | Prevents overheating and supports fuel efficiency |

Exhaust System | Controls gas flow and helps meet emission standards |

Cars use both centrifugal and axial blowers. Centrifugal blowers work well in hvac systems because they handle high pressure and are quiet. Axial blowers help cool the engine and move exhaust gases. As more people drive electric cars, there are more blowers made for battery cooling. Car makers keep making blower motors lighter and better at saving energy.

Note: If the air in your car does not move well or the temperature is hard to set, the blower motor might need to be checked.

Blower Fan Care

Signs of Malfunction

You can spot problems with your blower or blower motor by watching for certain warning signs. If you notice weak airflow from your vents, this often means something is wrong. Unusual noises like screeching, rattling, or banging can signal trouble inside the blower. High energy bills may show that your blower motor is working too hard. Overheating in your HVAC system or blower motor can also point to a problem. If you feel inconsistent temperatures in different rooms, your blower may not be moving air as it should. When your HVAC system turns on and off too often, this can mean the blower motor is struggling.

Here are some steps you can take to check for a bad blower motor:

Make sure there is a demand for the blower motor to run.

Test the bearings and see if the blower wheel spins freely.

Check the electrical supply and measure the voltage.

Test the capacitor for shorts or opens.

Inspect for dirt buildup and check belt tension.

Use special tools to test the blower motor if needed.

If you notice weak airflow, overheating, or strange noises, you may have a bad blower motor. Knowing when to consider replacing the blower motor helps you avoid bigger problems.

Maintenance Tips

Regular maintenance keeps your blower and blower motor running well. You should set up a maintenance schedule based on temperature and vibration checks. Use sensors to watch for changes that could mean trouble. Clean the fan wheels and keep them balanced to prevent damage. Replace shaft seals often to stop leaks and wear. Lubricate bearings and check them for smooth movement. Align and grease couplings and keep belt systems tight.

Follow these steps for better blower care:

Inspect your blower daily for leaks, vibrations, and noise.

Check air filters and belts every week.

Lubricate moving parts and check electrical connections each month.

Inspect bearings and replace seals every quarter.

Do a full system check every year.

Preventive maintenance can improve performance and extend the life of your blower motor. Studies show that regular filter changes can boost airflow by up to 46% and lower utility bills by 5-15%. Condition-based maintenance can cut system breakdowns by up to 75%. Good hvac system maintenance also reduces emergency repair costs and keeps your blower working longer.

Tip: If you notice weak airflow or rising energy bills, schedule a professional inspection. This helps you catch problems early and avoid a bad blower motor.

You now understand how a blower and blower motor work as a team. They keep air moving and help systems run well. Picking the right blower stops things from getting too hot. It also keeps your equipment safe. The blower motor moves air, so temperatures stay even. This helps the motor last longer.

Blower fans and motors that use energy well help you save money and stop damage to materials.

Top brands make blowers that are quiet, work well, and last a long time.

New tech makes blower motors smaller, tougher, and more dependable.

More factories and businesses need blower fans and blower motors as they get bigger.

Look at your blower and blower motor often. Clean them and take care of them to stop issues. If you notice weak air or odd sounds, fix it fast. Taking care of your blower and blower motor helps them last longer and work better.

FAQ

What is the main difference between a blower fan and a regular fan?

You will see that a blower fan pushes air in one set direction and creates higher pressure. A regular fan moves air in all directions and works best for open spaces.

How often should you clean your blower fan?

You should clean your blower fan every three to six months. Dust and dirt can build up quickly. Regular cleaning helps your blower work better and last longer.

Why does your blower fan make loud noises?

Loud noises often mean something is wrong. You might have loose parts, dirt buildup, or worn bearings. If you hear screeching or banging, turn off the fan and check for problems.

Can you replace a blower motor yourself?

You can replace a blower motor if you have basic tools and follow safety steps. Always turn off the power first. If you feel unsure, call a professional for help.